The Inner Structure and Main Types of Ball Mill:

Ball mill is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control. According the materials and discharging method, ball mill can be divided into dry type ball mill and wet type lattice ball mill.

According the materials and discharging method, ball mill can be divided into dry type ball mill and wet type lattice ball mill.

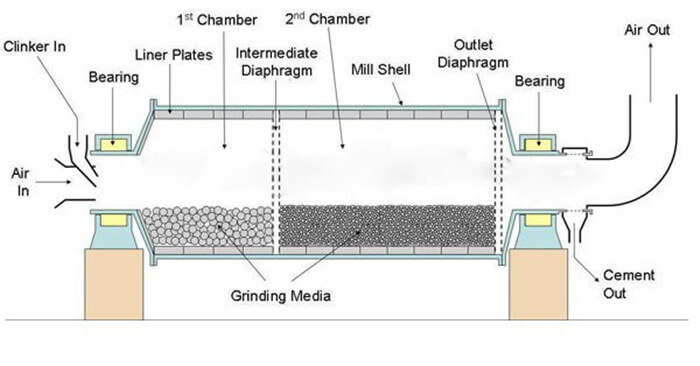

This machine is a horizontal type cylinder rotary device and outside the cylinder there is drive gear which drives the cylinder to rotate during the working process. Materials spirally and evenly go into the first cabin of the grinding machine through the feeding hollow shaft from the feeding device, and inside the first cabin, there are ladder lining boards or ripple lining board in which there are many steel balls with different specifications. The cylinder rotates and produces eccentric force to bring the steel balls to a certain height, and then the steel balls will fall down to impact and grind the materials. After being coarsely ground in the first cabin, the materials will go through the single-layer partition board and into the secondary cabin in which there are flat lining board, and in the lining board there are steel balls to further grind the materials. Finally the powdery materials will be discharged from the discharging grating bar to complete the powder grinding process.

|

Model |

Shell rotation speed |

Ball load |

Feeding size |

Discharging size |

Capacity |

Motor power |

Total weight |

|

Ф900×1800 |

36-38 |

1.5 |

≤20 |

0.075-0.89 |

0.65-2 |

18.5 |

5.85 |

|

Ф900×3000 |

36 |

2.7 |

≤20 |

0.075-0.89 |

1.1-3.5 |

22 |

6.98 |

|

Ф1200×2400 |

36 |

3 |

≤25 |

0.075-0.6 |

1.5-4.8 |

30 |

13.6 |

|

Ф1200×3000 |

36 |

3.5 |

≤25 |

0.074-0.4 |

1.6-5 |

37 |

14.3 |

|

Ф1200×4500 |

32.4 |

5 |

≤25 |

0.074-0.4 |

1.6-5.8 |

55 |

15.6 |

|

Ф1500×3000 |

29.7 |

7.5 |

≤25 |

0.074-0.4 |

2-5 |

75 |

19.5 |

|

Ф1500×4500 |

27 |

11 |

≤25 |

0.074-0.4 |

3-6 |

110 |

22 |

|

Ф1500×5700 |

28 |

12 |

≤25 |

0.074-0.4 |

3.5-6 |

130 |

25.8 |

|

Ф1830×3000 |

25.4 |

11 |

≤25 |

0.074-0.4 |

4-10 |

130 |

34.5 |

|

Ф1830×4500 |

25.4 |

15 |

≤25 |

0.074-0.4 |

4.5-12 |

155 |

38 |

|

Ф1830×6400 |

24.1 |

21 |

≤25 |

0.074-0.4 |

6.5-15 |

210 |

43 |

|

Ф1830×7000 |

24.1 |

23 |

≤25 |

0.074-0.4 |

7.5-17 |

245 |

43.8 |

|

Ф2100×3000 |

23.7 |

15 |

≤25 |

0.074-0.4 |

6.5-36 |

155 |

45 |

|

Ф2100×4500 |

23.7 |

24 |

≤25 |

0.074-0.4 |

8-43 |

245 |

56 |

|

Ф2100×7000 |

23.7 |

26 |

≤25 |

0.074-0.4 |

12-48 |

280 |

59.5 |

|

Ф2200×4500 |

21.5 |

27 |

≤25 |

0.074-0.4 |

9-45 |

280 |

54.5 |

|

Ф2200×6500 |

21.7 |

35 |

≤25 |

0.074-0.4 |

14-26 |

380 |

61 |

|

Ф2200×7000 |

21.7 |

35 |

≤25 |

0.074-0.4 |

15-28 |

380 |

62.5 |

|

Ф2200×7500 |

21.7 |

35 |

≤25 |

0.074-0.4 |

15-30 |

380 |

64.8 |

|

Ф2400×3000 |

21 |

23 |

≤25 |

0.074-0.4 |

7-50 |

245 |

58 |

|

Ф2400×4500 |

21 |

30 |

≤25 |

0.074-0.4 |

8.5-60 |

320 |

72 |

|

Ф2700×4000 |

20.7 |

40 |

≤25 |

0.074-0.4 |

22-80 |

380 |

95 |

|

Ф2700×4500 |

20.7 |

48 |

≤25 |

0.074-0.4 |

26-90 |

480 |

102 |

|

Ф3200×4500 |

18 |

65 |

≤25 |

0.074-0.4 |

As per process conditions |

630 |

149 |

|

Ф3600×4500 |

17 |

90 |

≤25 |

0.074-0.4 |

As per process conditions |

850 |

169 |

|

Ф3600×6000 |

17 |

110 |

≤25 |

0.074-0.4 |

As per process conditions |

1250 |

198 |

|

Ф3600×8500 |

18 |

131 |

≤25 |

0.074-0.4 |

45.8-256 |

1800 |

260 |

|

Ф4000×5000 |

16.9 |

121 |

≤25 |

0.074-0.4 |

45-208 |

1500 |

230 |

|

Ф4000×6000 |

16.9 |

146 |

≤25 |

0.074-0.4 |

65-248 |

1600 |

242 |

|

Ф4000×6700 |

16.9 |

149 |

≤25 |

0.074-0.4 |

75-252 |

1800 |

249 |

|

Ф4500×6400 |

15.6 |

172 |

≤25 |

0.074-0.4 |

84-306 |

2000 |

280 |

|

Ф5030×6400 |

14.4 |

216 |

≤25 |

0.074-0.4 |

98-386 |

2500 |

320 |

|

Ф5030×8300 |

14.4 |

266 |

≤25 |

0.074-0.4 |

118-500 |

3300 |

403 |

|

Ф5500×8500 |

13.8 |

338 |

≤25 |

0.074-0.4 |

148-615 |

4500 |

525 |