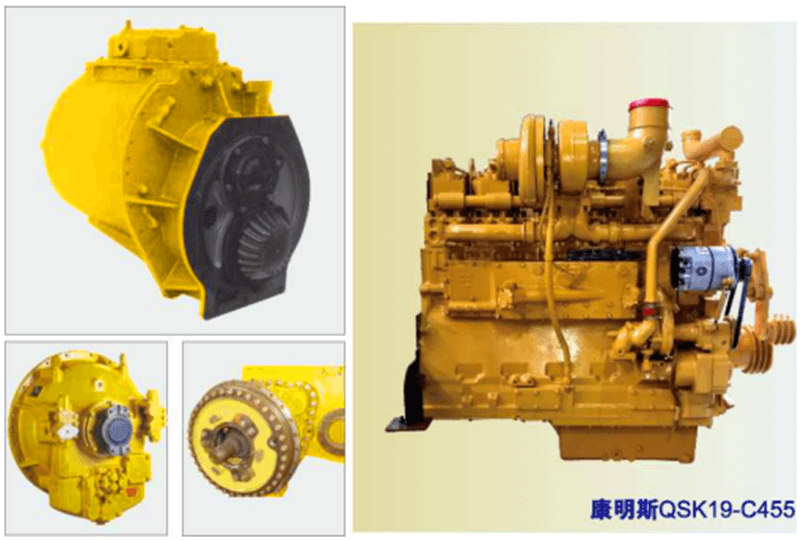

◊ Equipped with Cummins QSK19-C455 engine, more powerful and more reliable, compliant with national emission standard stage III.

◊ Hydraulic gearshift transmission for easier gear shifts and lower impacts.

◊ 3-element,single stage, single phase torque converter for higher efficiency and bigger capacity.

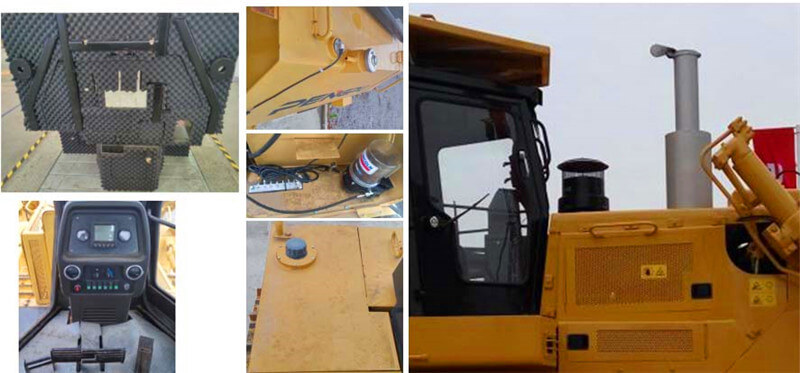

◊ Newly cab fora wide view, ROPS-FOPS structure for safety.

◊ Three-stage alarm electron monitor system effectively monitors the movement of the machine.

◊ Implement control is piloted for less operating efforts. Hydraulic system effects according to the load feedback to save fuel.

◊ More pleased appearance; Improved operating comfort.

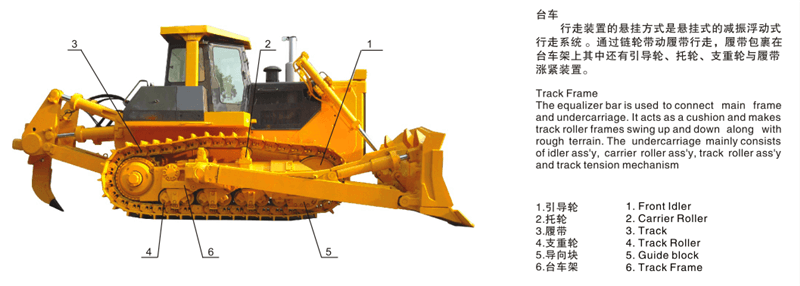

◊ New elastic and shock absorption track frame for increased adhesion force and added wheel life.

◊ Centralized lubrication for easy maintenance.

◊ Electric fuel feeder for easy fuel feeding.

◊ Centralized pressure checking for easier malfunction diagnosis.

◊ Automatic dust discharge type air precleaner adopted to remove dust efficiently

◊ Charged air cooling, Slow startup technology used in engine improves reliability, power output, fuel economy and exhaust emission.

◊ Efficient Holset Turbocharger provides increased intake air density,

◊ Resulting in more efficient combustion and more power; Charged air

cooling technology ensures fuel economy and lower emissions.

◊ Cummins proprietary PT fuel system with ultra-high injection pressure for better utilization of fuel and maximum combustion.

◊ Use of high strength alloy material, together with a sculptured cast-iron block for high rigidity, reduced vibration and low noise.

◊ Replaceable wet type cylinder liner for fast heat elimination and easier liner replacement.

◊ Cylinder block and head with inner lubrication circuits for a compact size and less malfunction.

◊ Use of gear centrifugal pump for force water cooling, together with big -flow water passages design, gives excellent cooling effect.

◊ Electronic control system with warning lamp for monitoring engine in jobs.

◊ Malfunction code corrective feedback for rapid service to engine.

Gearbox

This machine is equipped with transmission of planetary gear and multi-discs clutch hydraulic engaged and force lubricated {five transmitting lines in total). Forward 3 speeds and reverse 3 speeds can be gained hydraulically by actuating control valve.

Torque Converter

The torque converters are of the single stage, single phrase, 3 elements hydraulic type with reasonable structure and excellent reliability, which provide optimum matching with the machines. The outstanding transmissions comparing to the normal ones means the automatic adjustment to the field condition, gradually speed change, improved machine lifetime and traveling ability, easy maintenance, improved working comfort and torque limit set protection function.

Final drive

The final drive adopts double reductions of Spur gear pairs, planetary gear pairs to multiple torque and the power is transmitted to travel mechanism by driving gears. It features splash Lubrication and floating oil seal.

|

ENGINE |

QSK19-C455 CUMMINS |

|

RATED POWER |

340kW |

|

WEIGHT (VSD320Y-6) |

50500kg |

ENGINE

|

Model |

Cummins QSK19-C455 |

|

Type |

4-cycle, straight vertical, 6-cylinder, electronic injection, turbocharged, charged air cooled |

|

Rated power(kW) |

340KW |

|

Rated speed (r/min) |

2000 |

|

Number of cylinders-bore x stroke (mm) |

6-0159x159 |

|

Starting method |

Electric starting 8.25KVW24V |

|

Battery |

24V(12Vx2) |

|

Air cleaner |

Dry horizontal type with pre-cleaner |

|

Min fuel consumption ratio(g/kwh) |

227 |

TRANSMISSION

|

Torque converter |

3-element, single-stage, single-phase |

|

Gearbox |

Hand-operated, Hydraulic shift. Planetary gear, muliple- disc clutch, hydraulic-actuated, forced lubrication by gear pump, 3forward and 3 reverse speeds. |

|

Bevel gear |

Helical bevel gear, splash lubricated |

|

Steering clutch |

Wet, Multiple disc. Spring loaded, Hand-operated with booster and hydraulic-released |

|

Steering brake |

Wet, band brake, operated with hydraulic booster |

|

Final drive |

One Reduction, Interplanetary Gear, one Reduction, splash Lubricated |

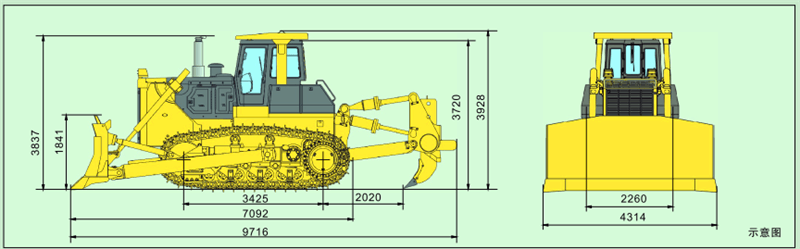

TRACK

|

Type |

Lubricated track |

|

Track pitch (mm) |

260.35 |

|

Track width(mm) Track width (mm) |

610 |

|

No. of track shoes (each side) No. of track shoes(each side) |

40 |

|

Length of track on ground (mm) Length of track on ground (mm) |

3425 |

|

Track gauge (mm) Track gauge (mm) |

2260 |

HYDRAUUC SYSTEM OF WORK EQUIPMENT

|

Working pressure (Mpa) |

20 |

|

Rated flow {L/min) (1700r/min) |

264 |

|

Pump |

CBY4160-145L gear pump |

|

Control valve |

Hydraulic- operated plungre, load response, pilot control |

|

Cylinder, Bore x Rod x Stroke (mm) |

<="" span=""> |

SUNDER CARRIAGE

|

Sprocket |

Segmented |

|

No. of carrier roller (each side) |

2 |

|

No. of track rollers (each side) |

6(4 Single, 2 double) |

|

Track tension |

Hydraulic - adjusted |

Floating seals are used in all sprockets, track rollers, carrier rollers and

Floating seals are used in all sprockets, track rollers, carrier rollers and

TRAVEL SPEED (km/h)

|

1st |

2nd |

3rd |

|

|

Forward |

3.4 |

6.7 |

12.2 |

|

Reverse |

4.2 |

8.0 |

14.8 |

WORK EQUIPMENT

|

Blade type |

Straight tilt blade |

|

Width x Height (mm) |

4310x1841 |

|

Max.lift above ground (mm) |

1620 |

|

Max.drop below ground (mm) |

749 |

|

Pitch adjustment (。) |

52 |

|

Max. Tilt (mm) |

1000 |

|

Blade capacity(m3) |

14.6 |

|

Ripper |

|

|

Type |

Single ripper |

|

Max. lift above ground (mm) |

1180 |

|

Weight (kg) |

5152 |