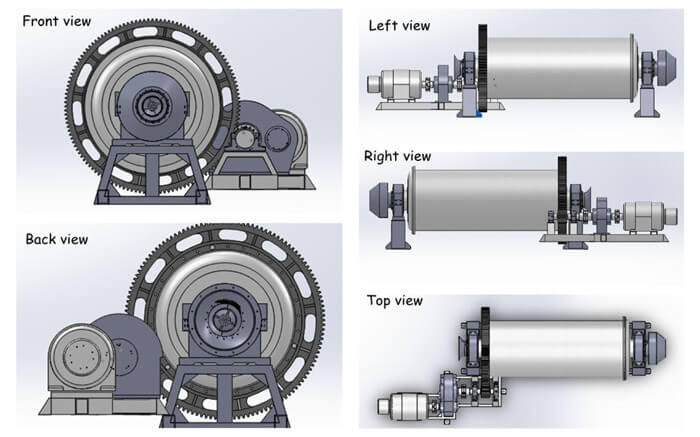

Cement mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries. Besides, it has two forms of milling, one is an open form, and the other is a recycle close form equipped with powder concentrator. It is widely applied in many industries and has convenient operation.

It has many advantages such as, strong adaptability, continuous production, large crushing ratio, easy to adjust the size of the products.

Working principle:

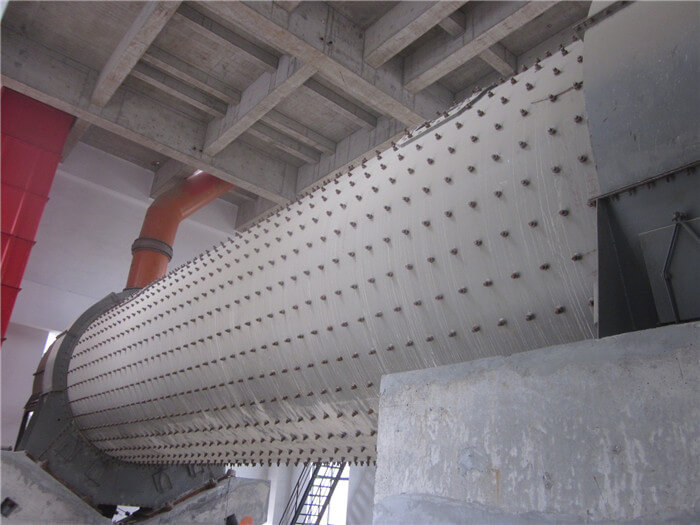

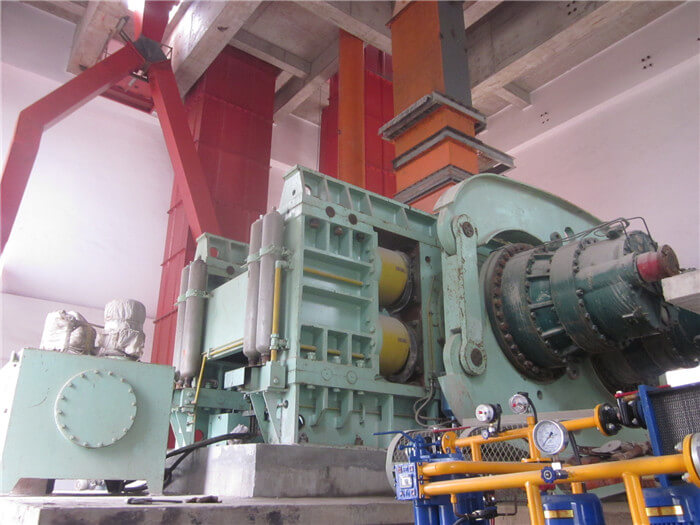

This ball mill is horizontal type and tubular running device, has two warehouses. This machine is grid type and its outside runs along gear. The material enters spirally and evenly the first warehouse of the milling machine along the input material hollow axis by input material device. In this warehouse , there is a ladder scale board or ripple scale board, and different specification steel balls are installed on the scale board, when the barrel body rotates and then produces centrifugal force ,at this time , the steel ball is carried to some height and falls to make the material grinding and striking. After grinded coarsely in the first warehouse, the material then enters into the second warehouse for regrinding with the steel ball and scale board. In the end, the powder is discharged by output material board and the end products are completed.

|

Spec. (m) |

Rotary speed(r/min) |

Feed size(mm) |

Capacity(t/h) |

Load of grinding media(t) |

Main motor |

Main reducer |

Weight (exclude motor and reducer)(t) |

|||

|

Model |

Power(kw) |

Speed |

Model |

Speed ratio |

||||||

|

Φ2.2×11 |

22.2 |

≤25 |

15~17 |

50 |

JR1512-8 |

570 |

740 |

ZD80 |

5 |

83 |

|

Φ2.4×8 |

20.91 |

≤25 |

14~18 |

39.5~42 |

JRQ1512-8 |

570 |

740 |

ZD80 |

5 |

76.4 |

|

Φ2.4×9 |

20.91 |

≤25 |

23~25(close) |

50 |

TR1512-8 |

570 |

740 |

ZD80 |

5 |

81 |

|

Φ2.4×10 |

20.91 |

≤25 |

16~18(open) |

50 |

TR1512-8 |

630 |

740 |

ZD80 |

5 |

92.4 |

|

Φ2.4×11 |

21 |

≤25 |

17~19(open) |

60~62 |

YR710-8/1180 |

710 |

740 |

JDX630 |

5.6 |

105 |

|

Φ2.4×13 |

21 |

≤25 |

21~22(open) |

66~68 |

YR800-8/1180 |

800 |

740 |

MBY710 |

6.3 |

117 |

|

Φ2.6×10 |

20.6 |

≤25 |

21~24 |

64 |

YR800-8/1180 |

800 |

740 |

JDX710 |

6.3 |

133 |

|

Φ2.6×13 |

20.6 |

≤25 |

28~31 |

80 |

YR1000-8/1180 |

1000 |

740 |

JDX800 |

6.3 |

151 |

|

Φ3.0×9 |

19.13 |

≤25 |

35~40(close) |

80~83 |

YR1000-8/1180 |

1000 |

740 |

MBY800 |

7.1 |

137 |

|

Φ3×11 |

18.92 |

≤25 |

44~47(close) |

95~100 |

YR1250-8/1430 |

1250 |

740 |

JDX900 |

7.1 |

159 |

|

Φ3×13 |

18.92 |

≤25 |

39~45(open) |

110~116 |

YR1400-8/1430 |

1400 |

740 |

JDX900 |

7.1 |

183 |

|

Φ3.2×11 |

18.3 |

≤25 |

45~48(close) |

110~112 |

YR1400-8/1430 |

1400 |

740 |

JDX900 |

7.1 |

195.5 |

|

Φ3.2×13 |

18.7 |

≤25 |

45~55(open) |

125 |

YR1600-8/1430 |

1600 |

740 |

JDX1000 |

7.15 |

213 |

|

Φ3.5×13 |

17.5 |

≤25 |

50~60 |

150 |

YR2000-8/1730 |

2000 |

740 |

JDSX1000 |

6.3 |

240.5 |

|

Φ3.8×13 |

16.3 |

≤25 |

65~70 |

185 |

YR2500-8/1730 |

2500 |

740 |

JS130-C-F1 |

|

220 |

|

Φ4×13 |

16.3 |

≤2 |

78~80 |

191 |

YRKK900 |

2800 |

745 |

JS140-A |

|

200 |

|

Φ4.2×11 |

15.6 |

≤2 |

120~140 |

190 |

YR2800-8/1730 |

2800 |

740 |

JS140-A-F1D |

|

245 |

|

Φ4.2×13 |

15.6 |

≤2 |

140~155 |

225 |

YRKK1000-8 |

3350 |

995 |

JS150-A |

|

260 |

|

Φ4.6×13 |

14.5 |

≤25 |

140 |

280 |

YR1000-6 |

4500 |

740 |

|

|

365 |

|

Φ5.0×15 |

14 |

≤25 |

160~165 |

350 |

YRKK1000-8 |

6000 |

740 |

|

|

420 |