Chicken Manure Rotary Dryer Application:

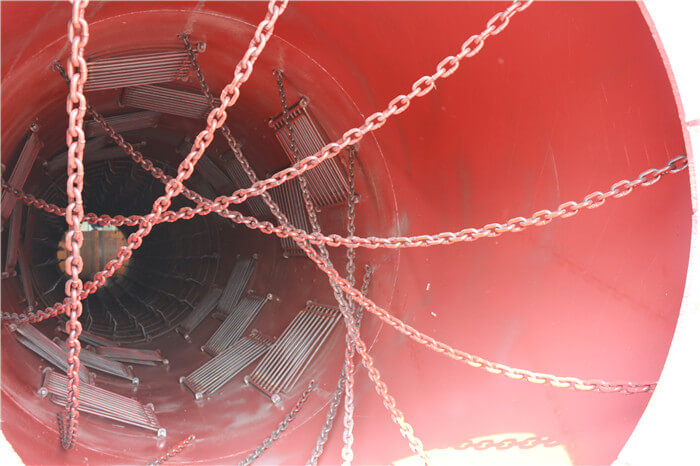

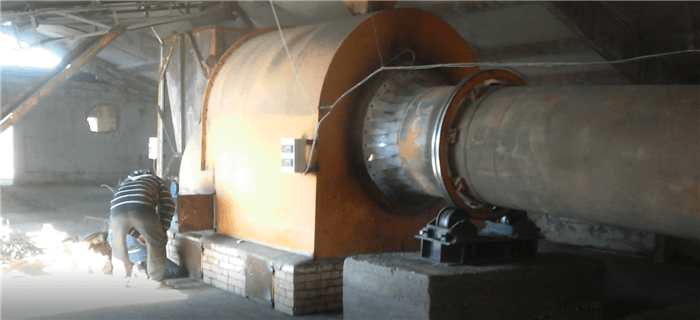

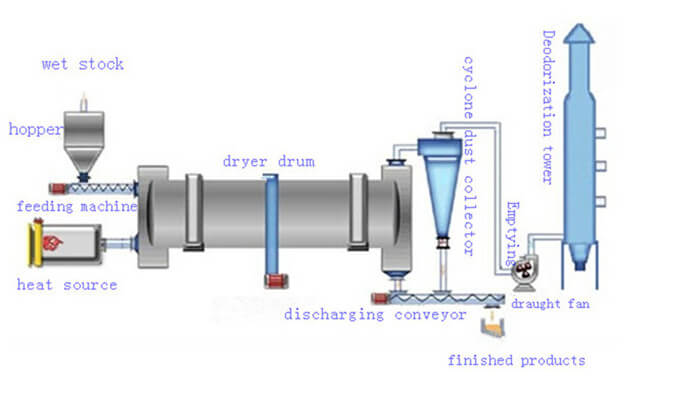

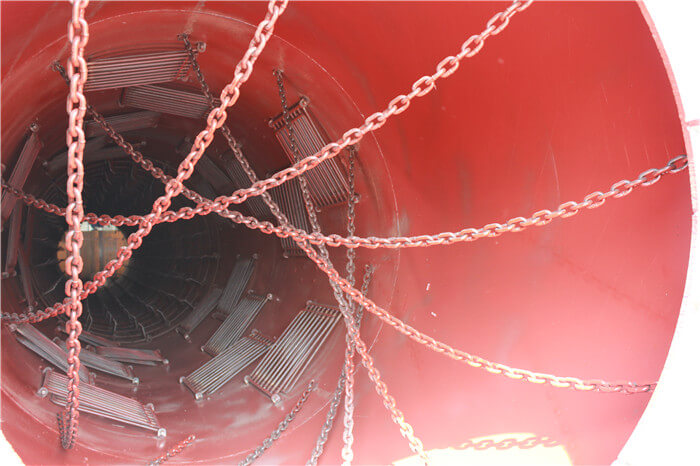

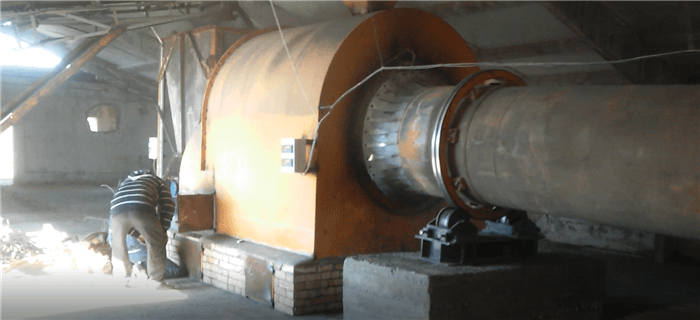

Manure Dryer, also known as rotary drum dryer. The machine has kept the ordinary drum advantages of the dryer, it is custom designed suit to the disadvantage of the moisture is more than 50% , Chains and movable turnboards can disperse materials and greatly improve drying efficiency and high fuel consumption etc. The material surface area fully expanded, to maximize heat transfer between the material and drying air. Because of the material particles to minimize and the heat transfer evaporation rate greatly improved.

This animal manure solid liquid separator used to reduce the water content of animal dung.The water content in the raw material can be 70-90%, and the moisture of final product is about 40%, you can’t press out any water by hands.

Chicken Manure Rotary Dryer Features:

1) This Manure dryer can realize the automatic and intelligent control, the operation parameters can be automatic control, the dryer is always in the best condition to running, it can be ensure uniform drying out of the raw material moisture is stability.

2) The inside of Manure rotary dryer has the unique flights to hits and tumbling the materials. In order to maximize efficiency of heat transfer between the material and drying air. The output of equipment increase more than 50% and the fuel energy consumption decrease more than 30%.

3) This machine uses four-wheel drive assembly. The driving is more stable and reliable.

4) The spatial footprint of general rotary drum dryer less footprint about 40%. The civil investment reduced about 40%. The equipment cost decrease about 20%.

5) The internal structure of the dryer use various efficient flight patterns. It can efficiency adjust the feed and heat distribution. The high heat efficiency, waste are exhausted temperature is lower than 50 ℃.

6) Adopts frequency motor control the material flow, heat supply, and drum rotate speed. It can easily adjust according to the needs of the outlet material moisture content and equipment output.

7) This type dryer use the modular dust collector purifying and heat recycling assembly. It is safe and protect environmental.

8) The Manure dryer is several options for new type energy-saving hot air furnace, high efficiency and energy saving, heating can be control, simple operation, energy consumption decrease about 30%, power consumption reduce 20%, and lower operation costs.

|

Spec.(m) |

Capacity (t/h) |

Main motor |

Weight (t) |

|

|

Power (kw) |

Model |

|||

|

Φ1.2×10 |

6-8 |

7.5 |

Y160M-6 |

12.5 |

|

Φ1.5×12 |

8-12 |

15 |

Y180L-6 |

16.5 |

|

Φ1.5×15 |

12-16 |

18.5 |

Y200L-6 |

18 |

|

Φ1.8×12 |

18-20 |

18.5 |

Y200L-6 |

20 |

|

Φ2.2×12 |

22-28 |

22 |

Y160L-6 |

37.6 |

|

Φ2.2×14 |

26-30 |

22 |

Y160L-6 |

40 |

|

Φ2.4×14 |

30-35 |

30 |

Y250M-6 |

51 |

|

Φ2.4×18 |

35-40 |

37 |

Y250M-6 |

54 |

|

Φ2.4×20 |

38-42 |

37 |

Y250M-6 |

54.14 |

|

Φ2.8×20 |

43-50 |

45 |

Y280S-6 |

71 |

|

Φ3×20 |

45-55 |

55 |

Y250M-4 |

78 |

|

Φ3×25 |

58-70 |

75 |

YR280M-4 |

93 |

|

Φ3.2×25 |

75-90 |

90 |

Y315M-6 |

156 |

|

Φ3.6×25 |

95-110 |

160 |

Y355L1-4 |

170 |

|

Φ3.6×28 |

80-140 |

200 |

Y355L2-4 |

180 |