Superior Reliability

By continuously optimization and innovation, we focus on improving product structure, upgrading raw material and optimizing assembly process. With all the advantages and advances automatic control system which is independently developed by VOSTOSUN, we can guarantee the reliability of our equipment.

VOSTOSUN MH/MS cone crushers have a wide field of application. They are suitable for various crushing process such as medium, fine and extra-fine crushing in mining, engineering and industrial areas. Customers can easily deal with different production needs by flexible choices of crushing chambers and eccentric throw.

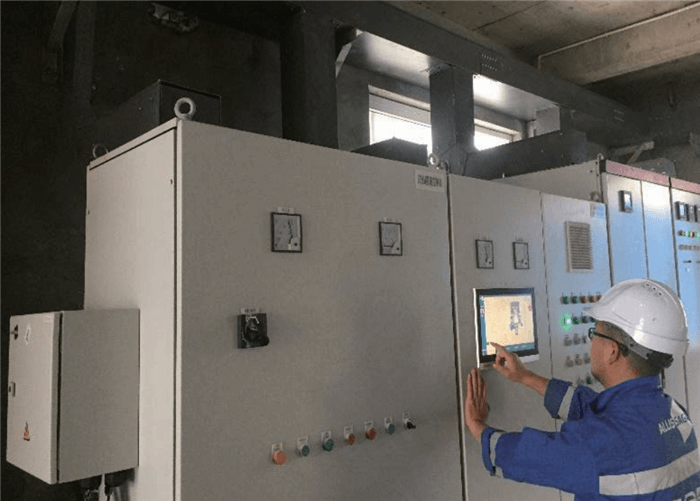

The automatic control system facilitate the operator to monitor and adjust crushing parameters at any time. Customers can make changing plan of the liners according to the parameters to minimize the downtime and cost. The dust sealing system and the strict sealing structure of the crusher minimize the equipment damage from dust and other fine particles, in other words, increase the life of crusher and reduce maintain cost. Optimal design of the hydraulic station and other parts make the operation and maintain much more easy, convenient and safe.

CIS is independently developed by VOSTOSUN. The system works on Windows platform which has greatly increased the reliability, compatibility and user-friendly function. Data sharing and remote control of the crusher operation are much easier and more reliable.

The main operation parameters of the crusher, such as crushing pressure, operation power and CSS, are oline display and easy to adjust. Almost all parameters of lubrication station, hydraulic station and electrical system to ensure the crushers always in high efficiency, safe and controllable state. Thanks to the strong memory traceability of CIS system, customers can trace the operation history and record to ensure safe and stable operation of the crushing system and to ensure that all maintenance could be scheduled on time.