The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc, and the ball mill can grind various ores and other materials with dry type and wet type.

Dry type ball mill has no water in the production, which is of straight cylinder with wind conducting device, dust discharging pipe and dust collector. We can design and manufacture other type of ball mill according to the customer's requirement, or by the customer's mineral sample, capacity and size dimension. By making ore grinding test and calculation, we can confirm the suitable model and type, and design the best working condition of the ball mill, making them that they have not only no functional shortage and also ensuring the capacity and size requirement.

Working principle of ball mill:

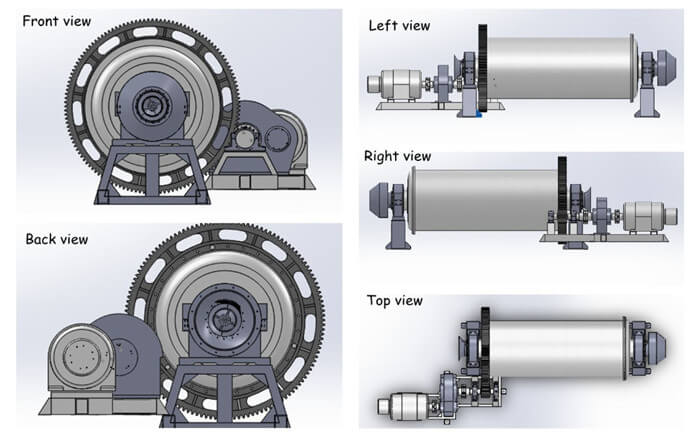

Ball mill include the feeding department, the exiting material department, the rotor, the transmission department (speed reducer, small transmission gear, electrical machinery, electric control) and so on main part composes.

Construction

Ball mill is composed of feeding part, discharging part, rotation part and driving part (gear box, small transmission gearwheel, motor and electric control). The hottest ball mill contains cylinder with wearable liners, which maintains the rotating of cylinder and the driving devices such as motor, transmission gear, pulley, belt, etc

|

Model |

Cylinder rotary speed (r/min) |

Loading ball weight(t) |

Input size (mm) |

Discharge size(mm) |

Capacity (t/h) |

Motor power (kw) |

Weight (t) |

|

Ø900×1800 |

39 |

1.5 |

≤20 |

0.075-0.89 |

0.8-2 |

18.5 |

4.6 |

|

Ø900×3000 |

39 |

2.7 |

≤20 |

0.075-0.89 |

1~4 |

22 |

5.6 |

|

Ø1200×4500 |

32 |

5 |

≤25 |

0.074-0.4 |

1.6-5.8 |

55 |

13.8 |

|

Ø1500×3000 |

27 |

7.5 |

≤25 |

0.074-0.4 |

2~5 |

75 |

15.6 |

|

Ø1500×5700 |

28 |

12 |

≤25 |

0.074-0.4 |

3.5-6 |

130 |

24.7 |

|

Ø1830×3000 |

25 |

11 |

≤25 |

0.074-0.4 |

4~10 |

130 |

28 |

|

Ø1830×6400 |

24 |

21 |

≤25 |

0.074-0.4 |

7~16 |

210 |

34 |

|

Ø2100×3600 |

23 |

19 |

≤25 |

0.074-0.4 |

10-36 |

210 |

46 |

|

Ø2200×4500 |

21 |

27 |

≤25 |

0.074-0.4 |

12~23 |

280 |

48.5 |

|

Ø2200×6500 |

21 |

35 |

≤25 |

0.074-0.4 |

14-26 |

380 |

52.8 |

|

Ø2200×7000 |

21 |

35 |

≤25 |

0.074-0.4 |

15-28 |

380 |

54 |

|

Ø2200×7500 |

21 |

35 |

≤25 |

0.074-0.4 |

15-30 |

380 |

56 |

|

Ø2400×4500 |

21 |

30 |

≤25 |

0.074-0.4 |

18-45 |

320 |

65 |

|

Ø2700×3600 |

21 |

39 |

≤25 |

0.074-0.4 |

19-75 |

400 |

83 |

|

Ø2700×4500 |

20 |

48 |

≤25 |

0.074-0.4 |

22-85 |

430 |

89 |

|

Ø3200×4500 |

18 |

65 |

≤25 |

0.074-0.4 |

29-140 |

800 |

137 |

|

Ø3200×5400 |

18 |

81.6 |

≤25 |

0.074-0.4 |

30-180 |

800-1000 |

146 |

|

Ø3600×4500 |

17 |

88 |

≤25 |

0.074-0.4 |

35-210 |

1000 |

190 |

|

Ø3600×8500 |

17 |

144 |

≤25 |

0.074-0.4 |

45-260 |

1800 |

260 |