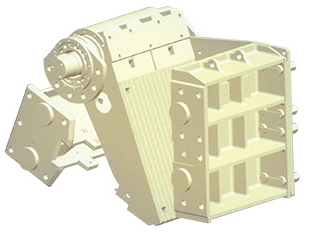

European Type Jaw Crusher Introductions:

Modular Series Jaw Crusher is the best choice for hard rock crushing process, fission structure makes installing and debugging work easier, it can shows its superiority in the pit. High speed crushing technique’s application makes high capacity and strong power and big crushing ratio. Reasonable shock absorption protects machine’s foundation.

Features:

1. 1. Toothed Plate

High manganese steel material and metallography detection make close connection of moving jaw and connecting plate, efficiency is increased.

2. 2. Feed Channel

Feed channel leads material to crushing cavity, and no need to remove it when changing toothed plate.

3. 3. Flywheel and V-belt

Flywheel and V-belt shield, besel of besel could be the way to observe the situation of Flywheel and belt pulley.

4. 4. Modular Structure

Free welding rack design lengthens machine’s service life. Parts of machine could be splited, transportation and installation costs can be reduced.

|

Model |

Size of Feed (mm) |

Max. Feeding Size(mm) |

Adjustable Size of |

Power(kw) |

Capacity(t/h) |

Dimension (L×W×H) |

Weight(t) |

|

C510×800 |

510×800 |

430 |

40-125 |

60/75 |

50-129 |

2480×1460×1750 |

8.3 |

|

C670×1000 |

670×1000 |

530 |

60-200 |

90/110 |

75-168 |

3090×1642×2300 |

15 |

|

C750×1130 |

750×1130 |

630 |

70-200 |

90/110 |

150-350 |

3228×1990×2500 |

22 |

|

C950×1250 |

950×1250 |

800 |

100-250 |

110/132 |

200-500 |

4184×2321×3245 |

39 |

|

C250×1200 |

250×1200 |

15-60 |

360 |

37 |

22-72 |

2108×1940×1680 |

6.9 |