【Introduction】:

A high efficiency and energy saving ball mill with rolling bearing

【 Capacity 】:

Up to 160t/h

【Improvement】:

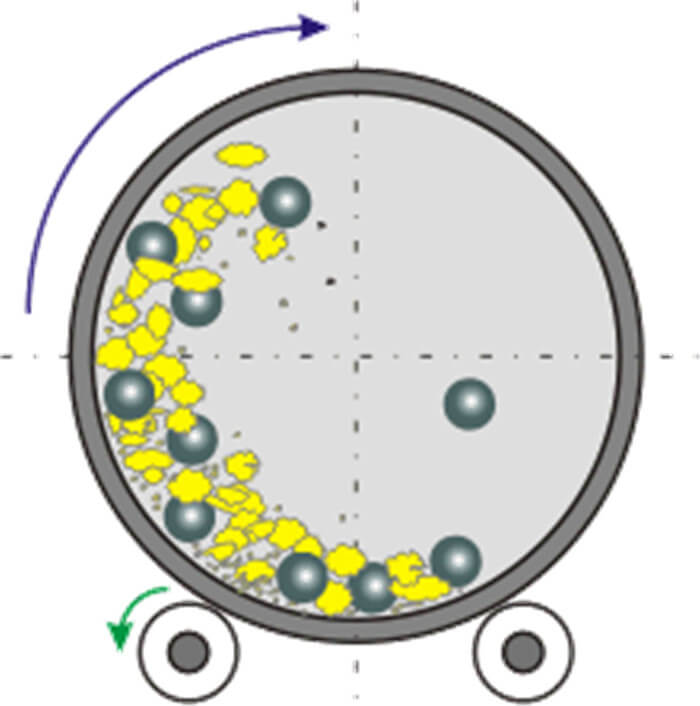

Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding.

The grate ball mill is usually used in the first segment of the two stages, or place of discharging the rough ore.

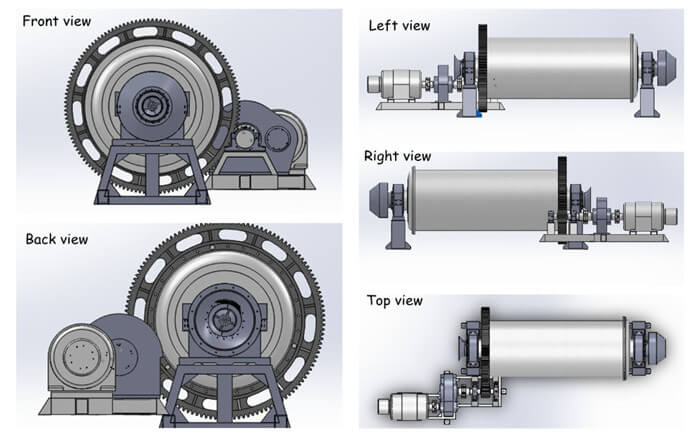

Structure:

The grate ball mill is roughly composed of the cylinder, cylinder liner,big gear ring, discharging grate,and ore feeding device. Except there is a discharging grate plate installed at the discharging end, all the other is similar with the overflow ball mill. The grate ball mill discharging cover head and grate plate have the structure as the drawing: grate liner, bearing inner cover, hollow shaft, dustpan liner, central liner, rib and wedge block.

In the head cover of the hollow shaft of the discharging end, it has bearing inner cover and discharging grate installed and the later is made from central liner, grate liner and dustpan liner etc. There are eight radial rib casted on the inner wall of the head cover, which divide the head cover into 8 fan rooms. There installed the dustpan liner inside each fan shape room, with the bolt fixed on the end cover. Finally the grate plate are installed on each fan room shaped by the dustpan liner. The grate liner has two kinds of structure: one is the group formed by two pcs, pressed by the wedge block, which get fixed tightly on head cover with the bolt getting through the rib. The central part are supported by the central liner to prevent them from declining and dropping off. The other kind is get two pcs into one block, fixing with bolt directly. The central liner is star shape, formed by two block, tightened on the rib with the bolt.

The hole on the grate liner is arranged at inclining direction. The wideth of the hole is getting bigger gradually to the discharging end, which can prevent the slurry from regorging and rough granularity from blocking. The slurry flow into the fan shape room through the hole on the grate plate from the lower part of the discharging end, and get passed up to the upper part along the cylinder rotating and discharged off the hole path. The hollow shaft neck has the grinding proof inner cover, with one end made of trumpet shape blade to lead the slurry to flow out of the mill.

As the slurry in this kind of mill is discharged through the grate plate, it is called the grate ball mill.

The characteristics of the grate ball mill:

1. The fast discharging speed, and high production capacity( 20~30% higher than overflow type, and so does power saving )

2. Less overgrinding phenomena--discharging at the lower horizontal level. Less slurry stored inside. And easy to discharge the grinded fine particles in time.

3. Much ball loading- not only big ball but also small ball, for the grate fence. Having the good grinding condition.

4. The complicated structure than overflow---multi grate fence, taking certain room and reducing the effective volume.

The grinded material are carried by the discharging grate plate in the grate ball mill, which has the compelling function, and fast discharging speed. The slurry level in the discharging end is lower than that of the lowest mother line level in the discharged shaft neck, so it is called the ore low level discharging. The mill has height difference from the material input end to the output end, and the slurry get through the mill with faster speed, discharging the grinded particles in time. As little slurry stored in the grate type ball mill and blocked by the grate plate, the mill can load more balls, easy to load the small ball. When the steel ball dropping off, the striking function lessened by the slurry resistence will be less. These causes make the production capacity and efficiency is higher than that of the overflow mill, with rough granularity finished product and not easy to get overcrushing.

|

Model |

Cylinder |

Cylinder |

Motor Model |

Motor |

Length |

Width |

Height |

Effective |

Max. Ball Load (t) |

Weight |

|

MQG0909 |

900 |

900 |

Y225S-8 |

18.5 |

4750 |

2213 |

2050 |

0.45 |

0.96 |

4620 |

|

MQG0918 |

900 |

1800 |

Y225M-8 |

22 |

5000 |

2280 |

2050 |

0.9 |

1.92 |

5340 |

|

MQG1212 |

1200 |

1200 |

Y225M-8 |

22 |

5788 |

2994 |

2540 |

1.14 |

2.4 |

11438 |

|

MQG1224 |

1200 |

2400 |

Y315S-8 |

55 |

6673 |

2994 |

2540 |

2.28 |

3.96 |

13200 |

|

MQG1515 |

1500 |

1500 |

JR115-8 |

60 |

6094 |

3300 |

2766 |

2.5 |

5 |

13700 |

|

MQG1530 |

1500 |

3000 |

JR125–8 |

95 |

7979 |

3300 |

2766 |

5 |

10 |

18690 |

|

MQG2122 |

2100 |

2200 |

JR128-8 |

155 |

7750 |

4839 |

3794 |

6.6 |

15 |

45400 |

|

MQG2130 |

2100 |

3000 |

JR137-8 |

210 |

8744 |

4394.7 |

3110 |

9 |

20 |

45790 |

|

MQG2430 |

2400 |

3000 |

JR1410-8 |

280 |

9728 |

4956 |

4018 |

12.1 |

22.5 |

67000 |

|

MQG2721 |

2700 |

2100 |

JR1410-8 |

280 |

9300 |

5500 |

4500 |

10.7 |

24 |

63000 |

|

MQG2727 |

2700 |

2700 |

JR148-8 |

310 |

9900 |

5500 |

4500 |

13.8 |

29 |

68530 |

|

MQG2736 |

2700 |

3600 |

TDMK400-32/2150 |

400 |

9765 |

5826.6 |

4674.5 |

18.4 |

41 |

98020 |

|

MQG3231 |

3200 |

3100 |

TDMK630-36 |

630 |

12750 |

6750 |

5152.5 |

22.5 |

45 |

115103 |

|

MQG3236 |

3200 |

3600 |

TDMK630-36 |

630 |

14300 |

6760 |

5200 |

24.8 |

58 |

119012 |

|

MQG3245 |

3200 |

4500 |

TDMK800-36 |

800 |

13896 |

7200 |

5152.5 |

32.8 |

65 |

137589 |

|

MQG3639 |

3600 |

3900 |

TDMK1000-36/3600 |

1000 |

15000 |

7200 |

6300 |

36.2 |

75 |

145000 |

|

MQG3645 |

3600 |

4500 |

TDMK1250-40 |

1250 |

15200 |

7750 |

6300 |

41.8 |

90 |

159700 |

|

MQG3650 |

3600 |

5000 |

TDMK1400-40 |

1400 |

17600 |

7750 |

6300 |

46.4 |

96 |

158000 |

|

MQG3660 |

3600 |

6000 |

TDMK1600-40 |

1600 |

17000 |

8800 |

6500 |

55.7 |

120 |

189000 |

|

MQG4060 |

4000 |

6000 |

TDMK1700-30 |

1700 |

17400 |

9500 |

7600 |

69.8 |

137 |

214000 |

|

MQG4560 |

4500 |

6000 |

TDMK2300-30 |

2300 |

17800 |

10500 |

7600 |

87 |

158 |

294000 |