IMPACT CRUSHER VSIP SERIES

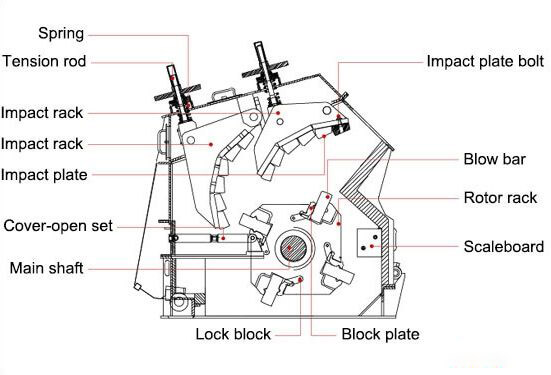

Impact crusher crushers material by striking energy. When it works, the motor drives the rotor rotate at a high speed, on which the low bar is installed. As soon as the material get into the affecting area of the blow bar, they will be stroke by the blow bar and be thrown to the impact devices around the rotor. The high speed forces the material to rebound from the impact liner to the area where the blow bar effects until they have been crushed to the required size. The clearance between the impact racks and the rotor can be adjusted to change the size and shape of the end products.

1.The space between the hammer and impact plate can be adjusted so that the discharging granularity can be controlled effectively and the particle is uniform in shape.

2.The material is crushed along the joint surface, so the power consumption is less and the working efficiency is high.

3.Non-key connected, easy maintenance, economical and reliable.

4. All crushing function with high capacity, the wear of machine parts is reduced so the benefits is high.

5.High chrome hammer is shock resistance and wear resistance with big impact force.

6.Simple in structure, small in size, light weight, high capacity and low cost. The feeding hole is big, crushing cavity is high and the material is hard.

7.Crushing ratio is as high as 40, so the crushing process is simplified which can reduce the times of crushing, which can reduce the cost of the equipment.

1.The space between the hammer and impact plate can be adjusted so that the discharging granularity can be controlled effectively and the particle is uniform in shape.

2.The material is crushed along the joint surface, so the power consumption is less and the working efficiency is high.

3.Non-key connected, easy maintenance, economical and reliable.

4. All crushing function with high capacity, the wear of machine parts is reduced so the benefits is high.

5.High chrome hammer is shock resistance and wear resistance with big impact force.

6.Simple in structure, small in size, light weight, high capacity and low cost. The feeding hole is big, crushing cavity is high and the material is hard.

7.Crushing ratio is as high as 40, so the crushing process is simplified which can reduce the times of crushing, which can reduce the cost of the equipment.

|

Model |

Specification |

Feeding Szie(≤mm) |

Production Capacity (T/H) |

Power(KW) |

|

VSIP-1000 |

1000*1000 |

250 |

30-60 |

55-90 |

|

VSIP-1250 |

1250*1050 |

300 |

60-100 |

90-132 |

|

VSIP-1250 |

1250*1400 |

300 |

70-140 |

132-185 |

|

VSIP-1325 |

1325*1500 |

300 |

100-150 |

180-260 |

|

VSIP-1500 |

1500*1500 |

350 |

180-280 |

280 |

Feedback from contact with us

Related Product

VERTICAL SHAFT IMPACT CRUSHER

Capacity:12-360T/H

Max. Feeding Size(mm): 26~60

Motor Power(KW): 2x30kw ~ 2x200kw

...

More >

SAND MAKER

Capacity:70-640T/H

Max feeding size(mm): 35~50

Double Motor power(KW): 110~440

...

More >

VERTICAL SHAFT SAND MAKER

Power(kw): 37~150

Capacity: 10-585 t/h

Max.feeding size(mm): 35~50

...

More >