Structure and Characteristics

1. Three-axle frame chassis system equipped with traction device is complied with the national semi trailer highway standards, which can be driven by standard tractor to achieve rapid transfer.

2. UMJ series is based on jaw crusher and vibrating feeder, combing transportation, receiving, feeding, pre-screening and crushing processes together to meet different crushing requirements.

3. The large hopper device can be used for direct unloading of loading vehicles.

4. The fixed legs and auxiliary legs can be used for different stretching support of transport and operation conditions.

5. The whole machine can be powered not only by diesel generators, but also by direct supply of electricity to meet different operation requirements.

|

Model |

Capacity (t/h) |

Weight (kg) |

Dimensions (Length*Width*Height)(m) |

Maximum feed size (mm) |

Discharge port adjustment range (mm) |

|

UMJ907 |

85-320 |

70000 |

17.1*5.42*6.378 |

895*660 |

50-180 |

|

UMJ1208 |

165-790 |

75000 |

17.1*5.42*6.945 |

1200*830 |

100-275 |

|

UMJ1211 |

300-805 |

85000 |

17.1*5.42*7.503 |

1200*1100 |

125-275 |

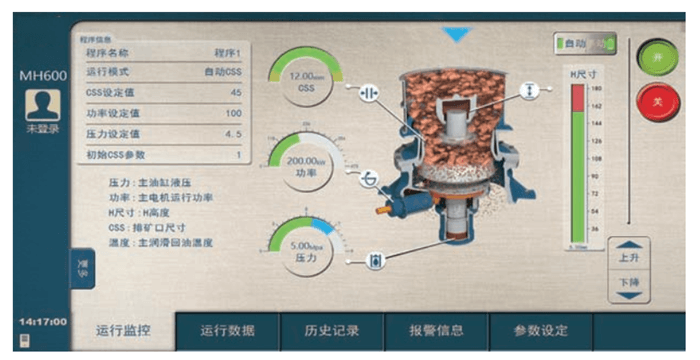

CIS is independently developed by VOSTOSUN. The system works on Windows platform which has greatly increased the reliability, compatibility and user-friendly function. Data sharing and remote control of the crusher operation are much easier and more reliable.

The main operation parameters of the crusher, such as crushing pressure, operation power and CSS, are oline display and easy to adjust. Almost all parameters of lubrication station, hydraulic station and electrical system to ensure the crushers always in high efficiency, safe and controllable state. Thanks to the strong memory traceability of CIS system, customers can trace the operation history and record to ensure safe and stable operation of the crushing system and to ensure that all maintenance could be scheduled on time.