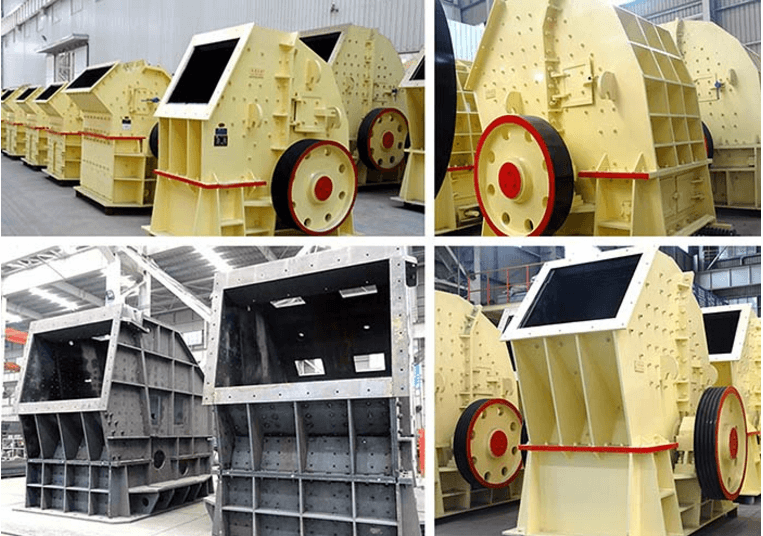

The Description and Advantages of PCZ Heavy Hammer Crusher:

PCZ Heavy Hammer crusherl is one type of the crushing machines and is also a machine with relatively advanced technology among the hammer crusher series in the present mining machinery industry. It uses advanced production technology and can realize one-time crushing, and it has the features ofhigh efficiency, energy conservancy and environment protection.

The Performance Characteristics of Heavy Hammer Crusher:

The final products can be adjusted according to the demands of the customers and the specifications of coarse, medium and fine particles are complete; and there are no flaky or smooth particles but plenty of angular particles to ensure the compression strength of the final products, so that they are very suitable for the construction of highway, buildings and large-sized projects.

The Application and Usage of PCZ Heavy Hammer Crusher:

This crusher gets rid of the primary crushing process of jaw crusher so that it has big output, high efficiency, and uses low energy, saves manpower and material resources and reduces the crushing cost of materials. This series of product is suitable for crushing various kinds of medium hard materials and crisp materials such aslimestone and coal in cement, mine, coal dressing, powder plant, chemistry and building material industry.

PCZ heavy hammer crusher is especially suitable for crushing limestone and medium hard stone materials whose compression strength is less than 200Mpa, which can crush the stone materials for one time without secondary-stage crushing and reshaping process, so that it can reduce the production cost by about 40% and the energy consumption is low and the investment is reduced.

The electromotor drives the rotor to rotate with high speed in the crushing chamber. The materials are fed into the machine from the upper feeding mouth and are crushed under the hitting, impacting, cutting and grinding of the hammer which is moving with high speed. On the bottom of the rotor, there is sieve plate and the crushed materials that is smaller than the screen size are discharged from the sieve plate, and the coarse particles bigger than the screen size are retained on the sieve plate to be hit and ground again by the hammer and finally be discharged from the machine from the sieve plate.

|

Model |

Rotor diameter×length |

Feed opening Length×width |

Feeding size |

Capacity |

Power |

Total weight |

|

PCZ1308 |

1300×1000 |

930×650 |

≤600 |

100-180 |

4P 132 |

2818×2100×2391 |

|

PCZ1410 |

1400×1000 |

1020×750 |

≤700 |

180-230 |

4P 160/2×90 |

2830×2100×2485 |

|

PCZ1610 |

1600×1000 |

1150×1000 |

≤900 |

260-350 |

4P 220-250/2×132 |

3370×2415×2751 |

|

PCZ1615 |

1600×1500 |

1400×1000 |

≤900 |

380-550 |

4P 355-400/2×200 |

3371×2925×2752 |

|

PCZ1716 |

1700×1600 |

1640×1300 |

≤1200 |

600-1100 |

4P 2×250 |

3520×3000×3210 |

|

PCZ1720 |

1700×2000 |

1980×1300 |

≤1200 |

800-1200 |

4P 2×400 |

3670×3390×3328 |

|

PCZ1920 |

1900×2000 |

1850×1600 |

≤1500 |

900-1500 |

2×500 |

3729×3300×4451 |

|

PCZ2225 |

2200×2500 |

2100×2300 |

≤1700 |

1500-3200 |

1250 |

3931×4100×4660 |