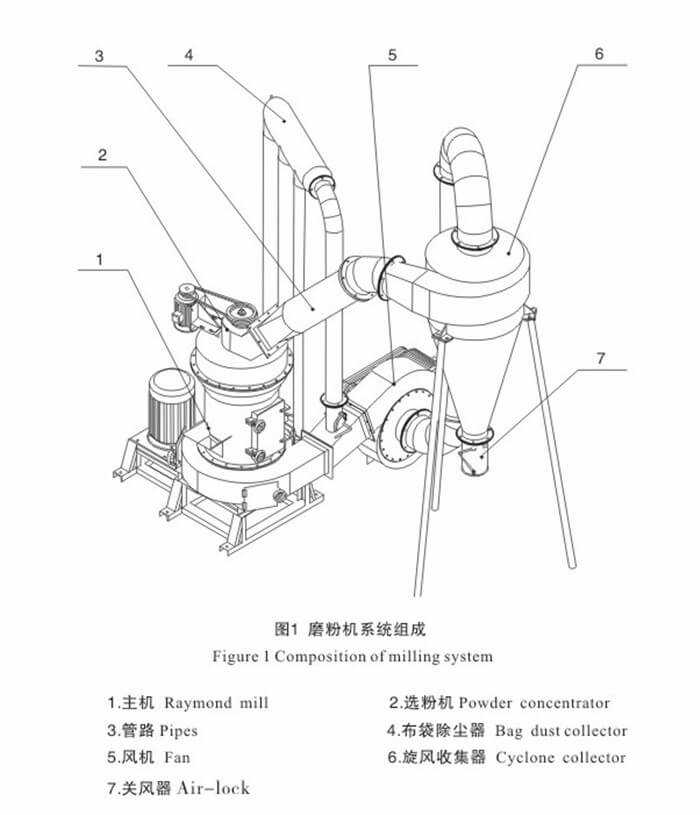

The Main Structure of Raymond Mill:

This machine is mainly composed of main engine, analytical engine, air blower, clone separator for final products, clone separator for micro powders and air pipe, and the main engine is composed of rack, inlet air volute, relieving tool, grinding roll, grinding ring and cover piece.

|

Model |

4525 |

4119 |

|

Feeding Size(mm) |

≤30 |

≤25 |

|

Output Size(mm) |

0.173-0.044 |

0.173-0.044 |

|

Shift Output of Different Material Fineness(t) |

16-176 |

8-78 |

|

Rotation Speed of Central Shaft(r/min) |

82 |

105 |

|

Ring Diameter(mm) |

1770 |

1400 |

|

Roller Diameter(mm) |

450 |

410 |

|

Roller Height(mm) |

250 |

190 |

|

Main Motor |

Y315M-4-132 |

Y280S-4-75 |

|

Fan Motor |

Y315M-4-132 |

Y280S-4-75 |

|

Analyzer Motor |

YCT250-4A-18.5 |

YCT200-4B-7.5 |