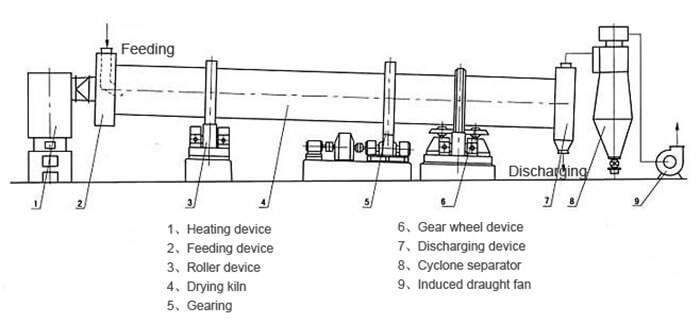

Working Principle

Since the dryer machine is obliquely installed, the materials flow to the lower end of the machine under the gravity and the rotation of the machine, and on the other hand, the materials are repeatedly lifted by the lifting board to the higher end and then spread down constantly, so that the materials will form a even curtain inside the cylinder and conduct heat exchange with the hot air inside the cylinder. Since the materials constantly spread and the water contained in them will be dried, thus achieving the aim of drying.

The drier is used in metallurgy, mining, chemical plant, for drying metal concentrates, tail ore and grain. It is also conventional drying equipment in cement plant. This machine has a good applicability for material and can dry various materials. It mainly consists of revolving part, raising stuff plate, driving device, seal ring and supporting device.

Sawdust dryer Advantages:

1. The hot flue gas directly contacts with the Sawdust, sufficient heat exchange and high production capacity.

2, Reasonable system configuration, it can use part of coal powder drying for fuel production, reduce costs and secondary pollution.

3, The system is equipped with PLC control system and video monitoring system, with a high degree of automation and simple operation.

4, The system through a unique sealing structure, no leakage.

5, Low investment, low operating cost, and short investment recovery time.

6, Use thicker carbon steel, famous motor power, full casting woke and management system to make sure Safe and Reliable operation.

Sawdust Dryer Features

1. High drying intensity: since the material is highly dispersed in the gas stream. The entire surface area of the particles is entire effective area of the particles for drying.

2. Short drying time.

3. Simple and compact structure, small floor area needed, convenient installation and maintenance.

4. Large drying capacity, high heat efficiency can be more than 70% when it is free water.

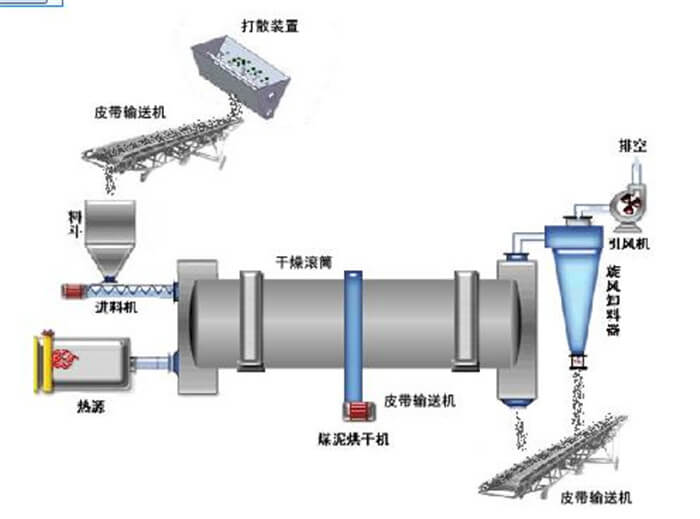

The Main Working Principle:

In the function of spray torch and rotary cylinder, sawdust goes into sawdust dryer. Material is bubbling fluidization in the drum, the hot air and material full access, then finishing drying.

|

Spec./m |

Shell Cubage |

Capacity |

Installation |

Highest Inlet |

Main Motor |

Weight |

|

Φ1.2×8.0 |

9.0 |

1.9~2.4 |

3~5 |

700~800 |

7.5 |

9 |

|

Φ1.2×10 |

11.3 |

2.4~3.0 |

3~5 |

700~800 |

7.5 |

11 |

|

Φ1.5×12 |

21.2 |

4.5~5.7 |

3~5 |

700~800 |

15 |

18.5 |

|

Φ1.5×14 |

24.7 |

5.3~6.6 |

3~5 |

700~800 |

15 |

19.7 |

|

Φ1.5×15 |

26.5 |

5.7~7.1 |

3~5 |

700~800 |

15 |

20.5 |

|

Φ1.8×12 |

30.5 |

6.5~8.1 |

3~5 |

700~800 |

18.5 |

21.5 |

|

Φ1.8×14 |

35.6 |

7.6~9.5 |

3~5 |

700~800 |

18.5 |

23 |

|

Φ2.2×12 |

45.6 |

9.7~12.2 |

3~5 |

700~800 |

22 |

33.5 |

|

Φ2.2×14 |

53.2 |

11.4~14.2 |

3~5 |

700~800 |

22 |

36 |

|

Φ2.2×16 |

60.8 |

13.0~16.2 |

3~5 |

700~800 |

22 |

38 |

|

Φ2.4×14 |

63.3 |

13.5~16.9 |

3~5 |

700~800 |

37 |

45 |

|

Φ2.4×18 |

81.4 |

17.4~21.7 |

3~5 |

700~800 |

37 |

49 |

|

Φ2.4×20 |

90.4 |

19.3~24.1 |

3~5 |

700~800 |

45 |

54 |

|

Φ2.4×22 |

99.5 |

21.2~26.5 |

3~5 |

700~800 |

45 |

58 |

|

Φ2.6×24 |

127.4 |

27.2~34.0 |

3~5 |

700~800 |

55 |

73 |

|

Φ3.0×20 |

141.3 |

30.1~37.7 |

3~5 |

700~800 |

75 |

85 |

|

Φ3.0×25 |

176.6 |

37.7~47.1 |

3~5 |

700~800 |

75 |

95 |

|

Φ3.2×25 |

201 |

42.9~53.6 |

3~5 |

700~800 |

90 |

110 |

|

Φ3.6×28 |

285 |

60.8~76.0 |

3~5 |

700~800 |

160 |

135 |

|

Shell |

Inside |

Inside |

Shell |

Shell |

Shell |

Lifting |

Highest |

Dimensions |

|

Φ1.5×15m |

1500 |

500 |

15 |

20.27 |

3-5% |

Lifting form |

850 |

16.2×2.7×2.7 |

|

Φ1.5×17m |

17 |

22.97 |

18.2×2.7×2.7 |

|||||

|

Φ1.5×19m |

19 |

25.68 |

20.0×2.9×2.9 |

|||||

|

Φ1.8×21m |

1800 |

650 |

21 |

35.91 |

3-5% |

Lifting form |

850 |

22.5×2.7×2.7 |

|

Φ1.8×23m |

23 |

39.33 |

24.5×2.9×2.9 |

|||||

|

Φ1.8×25m |

25 |

42.75 |

26.5×2.9×2.9 |

|||||

|

Φ2.2×21m |

2200 |

800 |

21 |

58.10 |

3-5% |

Lifting form |

850 |

---- |

|

Φ2.2×23m |

23 |

63.61 |

||||||

|

Φ2.2×25m |

25 |

69.15 |