|

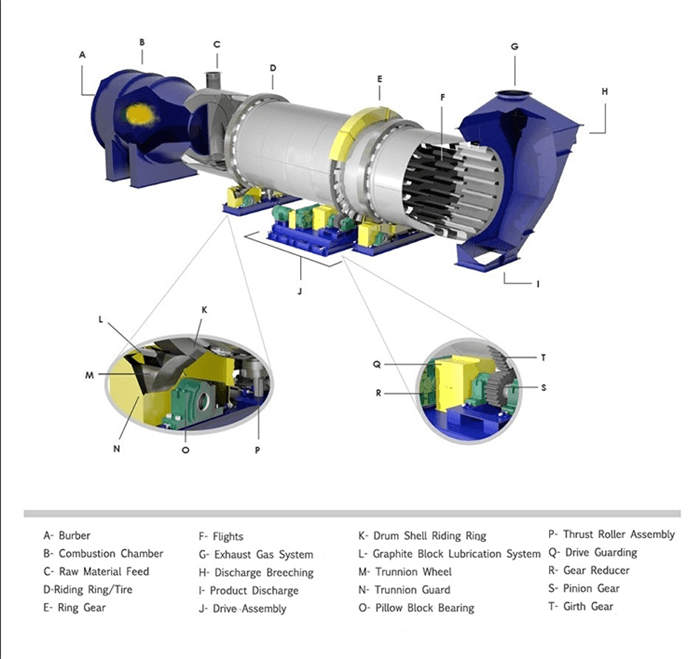

ROTARY DRYER |

|

|

Brief Introduction |

Rotary dryer is widely used to dry materials in industries like cement, mine, construction, chemical, food, compound fertilizer, etc. Thermocouples are installed in feeding and discharging units to control temperature. Temperature change of the dryer also can be indicated by the thermometer, which is convenient for temperature control inside the dryer ( it is usually 250-350℃). |

|

Applications |

Powder & particle: Sands, limestone, stones, clay, mineral filter cake, coal, iron sulphate, filter cakes, fly ash, gypsum etc. |

|

Features |

1.International standard with ISO, CE certificate. |

|

2.Simple system, safe and easy operation. |

|

|

3.Flexibility in fuels used (NG, Oil, Coal ect.). |

|

|

4.Year of experience with all types of dryers. |

|

|

5.Capable of installation anywhere in world. |

|

|

6.In house engineering for custom fit applications. |

|

|

7.Proven design. |

|

Point 1-Steel Plate Selection

Chemical analysis was carried out on the material inspection, according to the requirements of GB700-2006, dryer drum thickness < = 20 mm we use Q235 - A, > 20 mm we use Q235 - B; According to the GB/T 2970-2004 class ii, the range of 60 mm weld edge every board before cutting for ultrasonic flaw detection.

Point 2-Dryer Drum Welding

The dryer cylinder section for toroidal welding, longitudinal along the entire circumference of not more than two weld article number, and shell welds shall be full, the minimum is not lower than the parent metal surface, the top should not be higher than 3 mm, feed plate weld should be smooth. Weld edge bite depth should not be greater than 0.5 mm, continuous length should not be greater than 100 mm, should not exceed the total length of each weld bite edge which 10% of the weld length.

Point 3-nspection

Examination all the parts according to the drawing after processing completion. Spraying primer, rust preventing paint, and heat resistance paint.

Working principle:

It mainly consists of revolution body, raise material board, transmission device, supportive device and sealing ring, etc.

The heat sources of the drier is from the combustion train, and is adopts down-flow heating methods. When the materials enter into the body from the feeding device, it will be pushed back by the spire raising board. As the drier is in an inclined position, the materials will be down to the lower end under the influence of gravity and rotation, but the raising board will be threw to the upper end for scattering. This procession makes the material well-distributed in the body, and then ensure the heat exchange with the heat wind. After repeated cycle with this procession, the moisture content will be dried.

|

Spec.(m) |

Capacity (t/h) |

Main motor |

Weight (t) |

|

|

Power (kw) |

Model |

|||

|

Φ1.2×10 |

6-8 |

7.5 |

Y160M-6 |

12.5 |

|

Φ1.5×12 |

8-12 |

15 |

Y180L-6 |

16.5 |

|

Φ1.5×15 |

12-16 |

18.5 |

Y200L-6 |

18 |

|

Φ1.8×12 |

18-20 |

18.5 |

Y200L-6 |

20 |

|

Φ2.2×12 |

22-28 |

22 |

Y160L-6 |

37.6 |

|

Φ2.2×14 |

26-30 |

22 |

Y160L-6 |

40 |

|

Φ2.4×14 |

30-35 |

30 |

Y250M-6 |

51 |

|

Φ2.4×18 |

35-40 |

37 |

Y250M-6 |

54 |

|

Φ2.4×20 |

38-42 |

37 |

Y250M-6 |

54.14 |

|

Φ2.8×20 |

43-50 |

45 |

Y280S-6 |

71 |

|

Φ3×20 |

45-55 |

55 |

Y250M-4 |

78 |

|

Φ3×25 |

58-70 |

75 |

YR280M-4 |

93 |

|

Φ3.2×25 |

75-90 |

90 |

Y315M-6 |

156 |

|

Φ3.6×25 |

95-110 |

160 |

Y355L1-4 |

170 |

|

Φ3.6×28 |

80-140 |

200 |

Y355L2-4 |

180 |