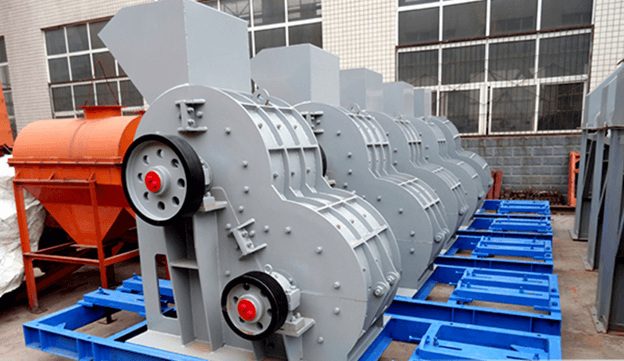

The Handling Materials and Description of Two Stage Crusher:

This machine is suitable for crushing feldspar, limestone, slag in the brick plant, construction wastes and so on, thus solving the problems of crushing high-humidity materials such as gangue and coal cinder which are often used as additive materials and fuel and for producing standard brick and air brick.

The Performance Characteristics of Two Stage Crusher:

1. Two-stage crusher is suitable for the fine crushing of crisp materials with no blockage, low powder dust pollution and low noise.

2. Two-stage crusher shortens the time that the materials stay in the crushing chamber, thus extending the service life of the easy-wearing parts.

3. The installation is very convenient, thus greatly improving the flexibility of the equipment.

This series of crusher continuously crushes materials through two rotors without grating bar device and all kinds of wet slag can be crushed. Even the materials that are just got out from water can be crushed and there will be no blockage. To control the material size, the workers can just adjust the gap between the two crushing hammers. As for the common crushers, since the materials often stay in the crushing chamber and block the it, so that the abrasion of the relevant spare parts will be intensified, but this series of crusher can totally avoid this.

Two-stage crusher adopts high alloy wear-resisting hammer, and the hammer and hammer handle can be used together, so that when the hammer is abraded, the workers can just change the hammer without changing the hammer handle.

Technical data

|

Specifition |

Capacity |

Motor Power |

|

ZPCΦ600×600 |

20-30 |

22kw×2 |

|

ZPCΦ800×600 |

35-55 |

45kw+55kw |

|

ZPCΦ1000×800 |

60-90 |

55kw+75kw |

|

ZPCΦ1200×1000 |

80-120 |

90kw+110kw |

|

ZPCΦ1400×1200 |

100-140 |

132kw+160kw |

|

ZPCΦ1600×1400 |

120-180 |

160kw+200kw |