APPLICATION SCOPE

High Pressure Grinder is designed by our institute through many years’ hard working study of powder processing machinery, which creates a new era of high-efficiency and low consumption grinding mill. This machine is suitable for producing minerals powder, which is widely used in the fields of mining, metallurgy, chemical, construction and mining industry. It can be used for grinding barite, limestone, porcelain, slag and other materials that Moh’s hardness is below 9.3, humidity is in 8%, and nonflammablenon -explosive minerals. The final product size can be adjusted as required in the range of80~425 meshes. And the special coarse powder device (30-80mesh) is also available

PRODUCT ADVANTAGES

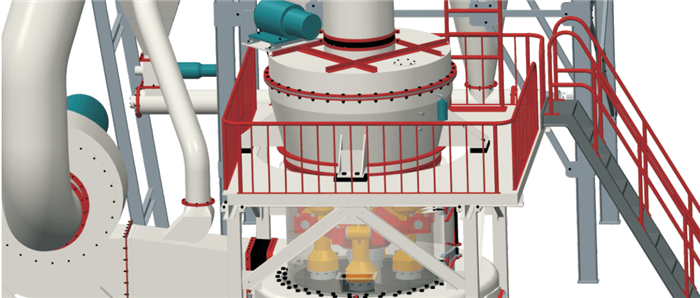

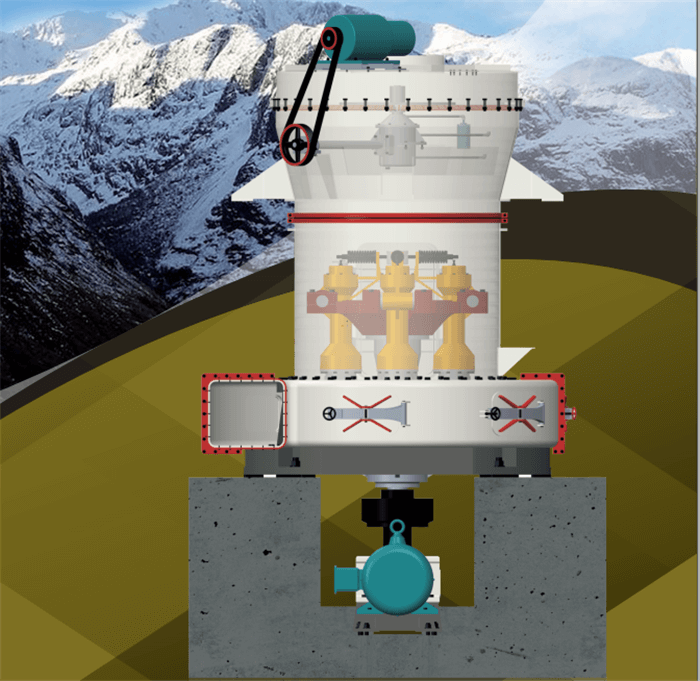

1. Compared with traditional Raymond Mill, with same driving force, it has about 10 -20% higher capacity. The grinding roller pressure to material increased 800- 1200kg by high pressure spring.

2. Material that Moh's hardness is below 9.3 is processable.

3. Final size has a wide range. Disc analysis machine or cage analysis machine is optional. The convenient variable frequency adjust electric machine enable final size 80-600 mesh. It is possible to produce 30-80 mesh coarse powder through special device in the machine.

4. The optimization and upgrading of key parameters such as appearance, roller ring diameter ratio, hanger assembly structure and rigidity, wind path system and so on, can improve the capacity, reduce energy consumption, protect environment.

5. Dust emissions meet the national standards. Pulse bag dust catcher can be adopted for quickly automatic ash removing.

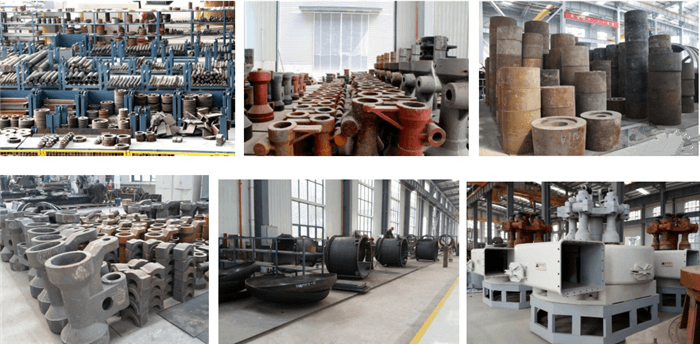

6. Roller assembly adopts new type multi-level seal structures, which can help to reduce maintenance ratio and maintenance charge.

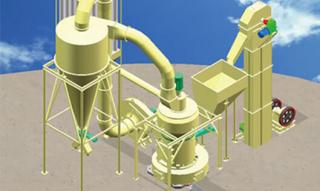

After been crushed into suitable size by jaw crusher, the raw material will belifted to hopper by elevator, and evenly fed into grinding chamber through feeder, then milled powder will rise with airflow of the fan and be classified. The qualified powder will be blown into cyclone collector, and then be discharged through valve as finished product. The whole grinding plant is a closed loop air system, and the air flow is under the condition of positive and negative state.

|

Models |

Quantity of Rollers (pcs.) |

Diameter×Height (mm) |

Feeding Size (mm) |

Output Size (mesh) |

Capacity (t/h) |

Host Speed (rpm) |

Main Power (kw) |

Power of Air Blower (kw) |

Power of Powder Selector (kw) |

External Dimension (mm) |

|

YGM(O)-75 |

3 |

780×150 |

≤15 |

30-425 |

1-3 |

160 |

18.5 |

15 |

2.2 |

4300×3500×5100 |

|

YGM(O)-85 |

3 |

830×140 |

≤20 |

30-425 |

1.2-4.5 |

150 |

22 |

22 |

4 |

5300×4100×5200 |

|

YGM(O)-95 |

4 |

950×170 |

≤25 |

30-425 |

2.1-5.6 |

130 |

37 |

30 |

5.5 |

7700×5900×7900 |

|

YGM(O)-130 |

5 |

1280×210 |

≤30 |

30-425 |

3.8-12 |

103 |

75 |

75 |

7.5 |

8000×8550×9700 |

|

YGM(O)-160-Ⅰ |

4 |

1600×270 |

≤35 |

30-425 |

7-22 |

90 |

132-160 |

132-160 |

11 |

10050×9400×9200 |

Note:The above capacity is standard output under 80% sieve-passing rate for grinding limestone, and the content of SiO2 is less than 1%. Any change, please check in the instruction manual. This series can be equipped different configurations according to different production requirement like material, final size,

technology, environmental protection and so on. Contact related business leaders if you have specific situation..

|

Models |

Quantity of Rollers (pcs.) |

Inner Diameter of Ring (mm) |

Feeding Size (mm) |

Output Size (mesh) |

Capacity (t/h) |

Host Speed (rpm) |

Main Power (kw) |

Power of Air Blower (kw) |

Power of Powder Selector (kw) |

External Dimension (mm) |

|

YGMX(O)-95 |

4 |

950×170 |

≤20 |

200-800 |

0.5-4.2 |

130 |

37 |

30 |

15 |

7700×5900×7900 |

|

YGMX(O)-130 |

5 |

1280×210 |

≤30 |

200-600 |

1.6-8 |

103 |

75 |

75 |

22 |

8000×8550×9700 |

|

YGMX(O)-160-Ⅱ |

4 |

1600×270 |

≤35 |

200-600 |

3.2-15 |

90 |

132-160 |

132-160 |

30-37 |

10050×9400×9200 |

|

YGMX(O)-190-Ⅰ |

4 |

1900×330 |

≤40 |

80-600 |

5-33 |

72 |

200-220 |

200-220 |

45-55 |

11700×10800×9300 |

|

YGMX(O)-190-Ⅱ |

4 |

1900×330 |

≤40 |

80-600 |

5.5-36 |

72 |

200-220 |

200-220 |

45-55 |

11700×10800×9300 |

Note: The above capacity is standard output under 80% sieve-passing rate for grinding limestone, and the content of SiO2 is less than 1%. Any change, please check in the instruction manual. This series can be equipped different configurations according to different production requirement like material, final size,

technology, environmental protection and so on. Contact related business leaders if you have specific situation..