Raw Materials:

Limestone, calcite, fly ash, calcium carbide, kaolin, calcium carbonate, coal gangue, gypsum, grain slag, ore slag, coal dust, bentonite, barite, marble, talc, refractory material

Application:

Metallurgy, construction materials, chemical engineering and other mineral materials grinding processing

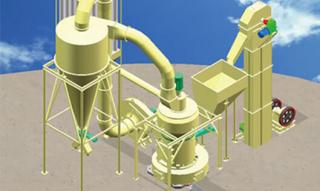

Upper-driven Vertical Mill is innovative high-end grinding equipment upgraded on the basis of original grinder by our senior powder experts who have learnt advanced grinding technology from home and abroad, combined with industry demand. This Type of grinder owns characteristics like high yield, low wear, operating intelligence, easy to maintain, durable, green and so on. Compared with other equipment on the market, it has unbeatable technical superiority and high performance price ratio, which is the best choice for large-scale pulverizing customers from electricity, building, mining, chemical engineering, paper-making, rubber, mixing plant, paint, environmental protection and other industries. It can be applied to grind non-flammable and unexplosive mineral materials that Moh's hardness below 9.3 such as limestone, calcite, quartz, feldspar, talc, barite, fluorite, tombarthite, marble, ceramics, bauxite, manganese ore, slag, grain slag, clinker, activated carbon, coal ash, soft coal, coking coal, kaolin, bentonite.

|

Model |

Rollers |

Inner Diameter |

Max.Input Size(mm) |

Host Speed |

Output Size |

Capacity |

Main Power(kw) |

Air Blower Powder(kw) |

Air Blower Powder(kw) |

Model of Pulse Dust Collector |

Power of Pulse Dust

Collector |

Model of Screw Conveyer |

Power of Screw

Conveyer |

Total

Weight |

|

SQLM1500 |

2 |

Φ1500 |

<40 |

105-115 |

30-600 |

12-90 |

315-400 |

315-400 |

55 |

DMC96 |

7.5 |

LS500*4500 |

11 |

120 |

|

SQLM2000 |

2 |

Φ2000 |

<50 |

81-92 |

30-600 |

19-120 |

630-710 |

630-710 |

75 |

DMC160 |

15 |

LS500*5058 |

18.5 |

300 |

|

SQLM2500 |

2 |

Φ2500 |

<60 |

65-75 |

30-600 |

30-200 |

1200 |

1200 |

90 |

DMC200 |

22 |

LS600*6500 |

22 |

450 |