Raw Materials:

granite, marble, basalt, iron ore, cobble, shale, bluestone, coal, cobblestone, construction waste

Application:

It's applied in crushing and screening line in metallurgy, coal, ore dressing, building materials, chemical industry and abrasive industry.

Vibrating feeder is for feeding block material for crushing and screening machine. It is divided into steel plate structure and grate structure two types; steel plate structure vibrating feeder is applied in stone and sand production line, grate structure vibrating feeder is for coarse screening material to make whole system more economical, it’s an essential machine in the crushing and screening line.GZD Series Vibrating feeer adopts vibration motor as the source of vibration, which has features of simple structure, high capacity, low maintenance rate. It can be widely used in the fields of metallurgy,construction, stone crushing, etc..While, ZSW Series Vibrating feeder adopts eccentric block as the source of vibration, gear drove by turns which has low vibrating noise, smooth operation, long usage. It can also pre-screen fine raw materials which makes higher effiency. The design of adjustable fence can prevent the materials from blocking in the gap.

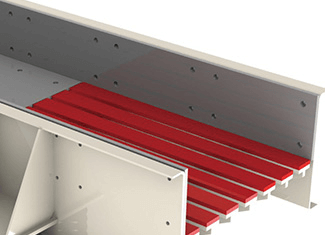

1.Grate

Grate clearance is adjustable according to requirement, backplate is removable to simplify maintenance and lengthen service life.

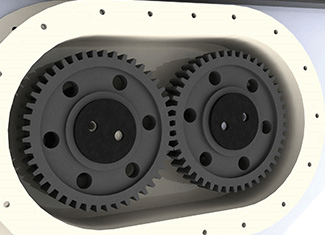

2.Gear

High strength and high high precision gear make stable working of machine.

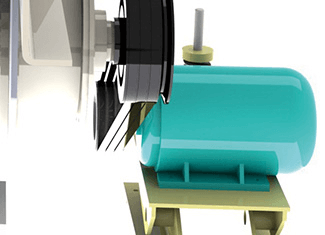

3.Motor

Famous motor brand, clients can choose Siemens brand.

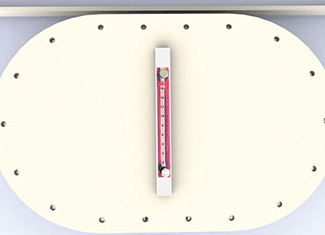

4.Oil quantity display

Clients can check the position of lubricating oil.

Technical Data

|

Model |

Max. Feeding Size(mm) |

Capacity (t/h) |

Motor Power Pole |

Power(kw) |

Installation Angle (angle) |

Size of Funnel (mm) |

Weight (t) |

Dimension (L×W×H)(mm) |

|

GZD-180×80 |

300 |

30-80 |

4 |

2×1.5 |

0-10 |

1800×800 |

0.8 |

1907×964×890 |

|

GZD-300×90 |

400 |

40-100 |

4 |

2×2.2 |

0-10 |

3000×900 |

1.5 |

3400×1020×900 |

|

ZSW-300×90 |

450 |

50-150 |

6 |

7.5 |

0-10 |

3000×900 |

3.5 |

3080×1650×1180 |

|

ZSW-380×96 |

500 |

120-210 |

6 |

11 |

0-10 |

3800×960 |

4.2 |

3880×1724×1180 |

|

ZSW-420×110 |

650 |

180-400 |

6 |

15 |

0-10 |

4200×1100 |

4.8 |

4200×1804×1180 |

|

ZSW-490×110 |

650 |

250-480 |

6 |

15 |

0-10 |

4900×1100 |

5.3 |

4976×1864×1180 |

|

ZSW-490×130 |

800 |

300-550 |

6 |

22 |

0-10 |

4900×1300 |

6.7 |

4976×2064×1180 |

|

ZSW-600×130 |

800 |

340-600 |

6 |

30 |

0-10 |

6000×1300 |

7.8 |

6100×2004×1250 |

|

ZSW-600×160 |

1050 |

400-800 |

4 |

37 |

0-10 |

6000×1600 |

10.8 |

6400×3085×2395 |