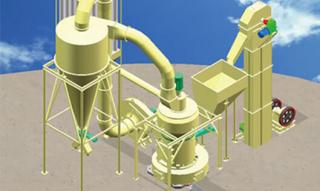

Wet pan mill is widely used for selecting ferrous metals, nonferrous metals and nonmetals, as well as precious metals like gold and silver. Based on the different structure it is divided into double roller grinding and three roller grinding. It grinds ores by wheel driving force. firstly, the power is transferred from the motor to the reducer, then to the horizontal shaft, and finally to the grinding wheel; the wheels then rotate anticlockwise.The wheels can revolve around the vertical shaft of the pan mill, at the same time, it can revolve on its own axis, while the grinding base will remain still. The ores are pressed, rubbed and grinded repeatedly.

Working Principles of wet pan mill

1) When inputting gold sand into the rolling drum, the rollers compress the sand over and over into tiny particles.

2) Please put in 5 kg mercury at first, the mercury can absorb the gold or other metals.

3) At last, use a high-density red cloth to wrap mercury up.

4) Then squeeze it, the mercury will be pressed out and pure gold stayed.

5) As to the large capacity, we can use mercury shaking machine and mercury steamer to replace the manual work.

Advantages of wet pan mill

1) The grinding wheels mix up the ores and produce ore pulp while pressing and rubbing the ores.

2) The ores and water are evenly mixed, which makes the pulp density and other indexes stable.

3) After the grinding process, the monomers are taken to the upper surface of the pulp and discharged through the overflow outlet of the water basin. Meanwhile, the coarse ores sink to the bottom of grinding base, being grinded continuously till they reach the required fineness.

4) The screening mesh set up at the overflow outlet of the water basin classifies the ore fineness strictly to avoid the over-grinding and uneven fineness, which helps create better condition for next working process.

|

Model |

specification |

Input size (mm) |

Process ability (t/h) |

Speed (r/min) |

Motor (kw) |

Weight (t) |

|

1600 |

1600×400×±20 |

less than 30 mm |

4 |

20—22 |

6—30 |

17 |

|

1500A |

1500×400×±20 |

3 |

20—22 |

6—22 |

15 |

|

|

1500B |

1500×350×±20 |

2.5—3 |

20—22 |

6—22 |

14 |

|

|

1500C |

1500×300×±20 |

2—2.5 |

20—22 |

6—22 |

12.5 |

|

|

1400 |

1400×250×±20 |

1.5—2 |

16—18 |

6—18.5 |

9.5 |

|

|

1300 |

1300×250×±20 |

1.5 |

21—23 |

6—15 |

7.8 |

|

|

1200A |

1200×220×±20 |

0.9—1.2 |

16—18 |

4—7.5 |

6.0 |

|

|

1200B |

1200×200×±20 |

0.8—1 |

21—23 |

4—7.5 |

5.8 |

|

|

1100 |

1100×200×±10 |

0.6—0.8 |

16—18 |

4—5.5 |

5.5 |

|

|

1000 |

1000×200×±10 |

0.5 |

21—23 |

4—5.5 |

4.5 |

|

|

900 |

900×150×±10 |

0.3 |

17—19 |

3 |

3.2 |