WHEEL LOADER SEM660D

resSpecificationWork ToolsPhoto

Optimized Engine

- Low speed engine with E-fan provides increased operating efficiency

- Enhanced fuel pre-filter eliminates water and contaminant from fuel for best fuel system protection

- The 93 desert type air cleaner provides machine reliability in most severe applications. Oil-bath type oil filter is optional

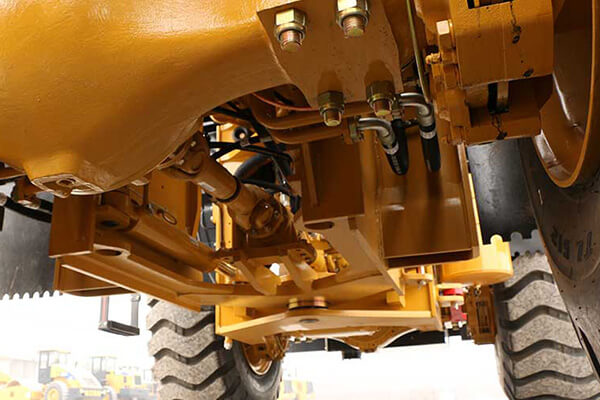

Efficient Hydraulic System

- The advanced load sensing hydraulic system with flow sharing circuits improves efficiency

- World Class hydraulic components ensure high reliability

- The optimized hydraulic system paired with the drive train reduces machine cycle time and increases productivity

- Relocated hydraulic oil tank ensures hydraulic pump’s life

Operator Station

- Premium operator station improves cab sealing and visibility

- Sliding side window and AC with fresh air circulation provide operator comfort

- Integrated relays and fuse panel. Single cabin harness connection plug provides easy service access

- Joystick hydraulic control for easy and precise operation命

- Multi-function instrument dashboard with 3-level alarm

- Adjustable suspension seat

Reliable Drivetrain

- Countershaft transmission with upgraded core components provides high reliability

- Large rim-pull in 1st gear and higher speed in 2nd gear provide high efficiency for load and carry applications

- Clutch cutoff selection switch ensures stable and safe operation

- The SEM designed and built axle equips with 10 calipers (6 for front and 4 for rear), it delivers better brake performance and longer service life

Advanced Cooling System

- The standard cooling package provides high reliability in 43°C ambient conditions. An optional package is available for 50°C ambient conditions

- Shock pad mounts ensure reliability under severe applications

Solid Structure

- Structures undergo Finite Element Analysis (FEA) and On Machine Stress Analysis (OMSA) to ensure durability

- Performance Series (PS) buckets improve loading capability

- Steering robber stopper design provides protection for frame

Serviceability

- Torque convertor is isolated from transmission making it easy to service

- Simple structure countershaft transmission delivers low maintenance cost

- Centralized lubrication points reduce maintenance time

- System pressure test ports are standard

- Easy access to external air charge connecting port

- Engine hood grill opens for easy service access

- It is easy to change brake discs with new split type caliper

Safety

- Safety design complies with all regulatory requirements

- Caterpillar Production System (CPS) leveraged in manufacturing process

- 3-point touching design provides convenient operator entering to cabin

- Backup alarm and beacon ensure machine safety

- Environment-friendly painting process

Multiple Applications

- SEM660D can be widely used in port cargo handling mineral yards, steel mill,and other high productivity demand applications

- In aggregate site, coal loading and construction etc loosen material handling utilization applications,SEM660D can load more, move faster and burn less

- Multiple work tools for selection

| Item | Unit | Params |

| Main Specifications | ||

| Rated Load | kg | 6000 |

| Operating Weight with Standard Bucket | kg | 20000 |

| Bucket Capacity | m³ | 3.3-5.5 |

| Wheel Base | mm | 3350 |

| Overall Dimension (outside of tire) | mm | 8414X3370X3458 |

| Operating Specifications | ||

| Breakout Force (GRD) | kN | 183 |

| Dump Clearance | mm | 3 048 |

| Articulated Angle | ° | 38±1 |

| Transmission | ||

| Transmission Type | Countershat, power shift | |

| Transmission Gears | F4/R4 | |

| Torque Converter Type | Single stage 3 elements | |

| Maker & Type | TR200 | |

| Forward 1/ Reverse 1 | km/h | 7.4/7.4 |

| Forward 11/ Reverse II | km/h | 14/14 |

| Forward III/ Reverse III | km/h | 22/22 |

| Forward IV/ Reverse IV | km/h | 38/38 |

| Axle | ||

| Main Drive Type | Spiral bevel gear, single stage | |

| Final Drive Reduction Type | Planetary type, single stage | |

| Rear - Oscillating +/- | ° | ±11 |

| Engine | ||

| Engine Model | WD10G240 | |

| Rated Power | kW | 178 |

| Rated Speed | r/min | 2000 |

| Displacement | L | 9.726 |

| Implement Hydraulic | ||

| Implement System Type | Single load sensing flow sharing system | |

| Boom Raise Time | s | 5.3 |

| Hydraulic Cycle Time (rated payload) | s | 9.7 |

| System Presure Setting | Mpa | 18 |

| Brake System | ||

| Service Brake | Dry & caliper, air to oil control | |

| Parking Brake | Drum type shoe brake,spring applied & oil released | |

| Steering System | ||

| System Type | Flow amplifying | |

| Steering Pump Type | Piston pump | |

| System Presure Setting | Mpa | 18 |

| Steering Angle (L/R) | ° | 38±1 |

| Tires | ||

| Size | 23.5-25 | |

| Type | Bias | |

| Layer | 20 | |

| Textured Type | L3/E3 | |

Feedback from contact with us