◊ The appearance of the vehicle is based on optimization design.

◊ High engine power reserve, strong torque output, low fuel consumption, reliable controls.

◊ Hydraulically powered, automatic speed change, shift the gears without stop the vehicle.

◊ 3 elements, single stage and single phase torque convertor features high efficiency and capacity.

◊ The updated hexahedral cab features outstanding visibility and good tightness.

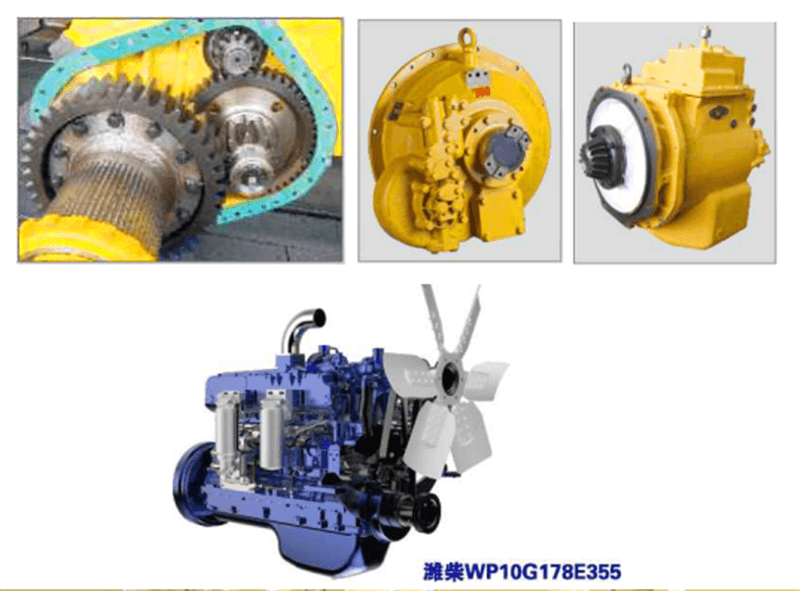

◊ Using the triangle spline and the gear of crowned teeth and tip relief in the final drive to average the loads on the trans-mission components for more stability, prolong the lifetime.

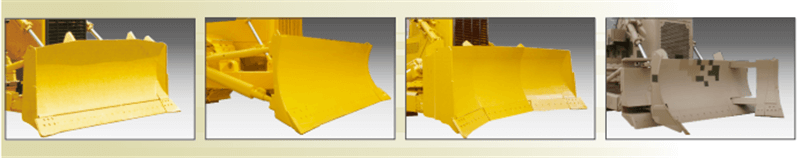

◊ New blade is more durable and capacious.

◊ Alarming & monitoring system is reliable.

◊ Reliable manual - operated spool valve and external mounted valve for easy maintenance.

♦ 4 valve design for efficient combustion and excellent fuel economy.

♦ 3-stage fuel filtration system for more choice on oils.

♦ 93 dust filter for reduced parts wear by 90%.

♦ Turbocharger adaptable for working at an altitude more than 4000m.

♦ Inner located relay starter controlled by ECU for reduced failure.

♦ Intake air heating grille makes engine start at -35°C possible.

♦ Large-flow inner thermostat for easy service and reduced operating cost.

♦ Hyperboloid fan features large air flow and low noise.

♦ Self-check generator with avalanche diode and self-driven adjustor

for excellent reliability.

♦ Reinforced oil pan for less noise radiation. Service hours of CH grade oil: 500h.

Gear Box

The gear box is of the planetary gears type, by operating hydraulic control valve for traveling forward and backward. It features planetary gears, multi-disc clutch, hydraulically applied forced lubrication, 3 speeds forward and 3 speeds backwards.

Torque Converter

The torque converters are of the single stage, single phrase, 3 elements hydraulic type with reasonable structure and excellent reliability, which provide optimum matching with the machines. The outstanding transmissions comparing to the normal ones means the automatic adjustment to the field condition, gradually speed change, improved machine lifetime and traveling ability, easy maintenance, improved working comfort and torque limit set protection function.

The Final Driving

For tip relieve and crowned gears which features large loading capacity, stable transmission and long lifetime.

|

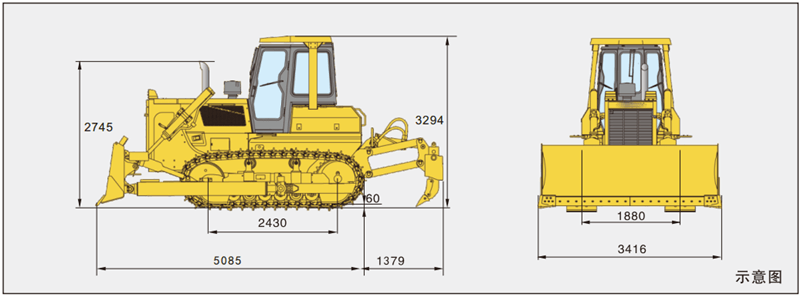

ENGINE |

Wechai WP10G178E355 |

|

RATED POWER |

131kW |

|

WEIGHT (VSD165Y-5) |

16700kg * |

|

WEIGHT (VSD165YS-5) |

18700kg * |

ENGINE

|

Model |

Wechai WP10G178E355 |

|

Type |

Straight vertical, vertical, four-stroke, water cooling, direct injection type |

|

Flywheel (kW) |

121 |

|

Power(kW) |

131 |

|

Rated speed (r/min) |

1850 |

|

Number of cylinders-bore x stroke (mm)

|

6-126x130 |

|

Starting method |

24V, 5.5kW, Electric starting motor 24V, 5.5kW |

|

Battery |

24V (12Vx2) |

|

Air cleaner configuration |

Dry type, radial seal 93 dust filter configuration. |

|

Min fuel consumption ratio(min) (g/kw • h) |

191.2 |

TRANSMISSION

|

Torque converter |

3-element, single-stage, single-phase |

|

Gearbox |

Hand-operated, Hydraulic shift, Planetary gear, multiple disc clutch, forced lubrication by gear pump |

|

Bevel gear |

helical bevel gear. Splash lubricated |

|

Steering clutch |

Wet, Multiple disc,Spring loaded, Hand-operatedwith booster and hydraulie- released |

|

Steering brake |

Wet, band brake, operated with hydraulic booster |

|

Final drive |

Spur gear, double reduction, splash lubricated |

|

TRACK |

|

|

Type |

Sealed and lubricated single grouser or sealed single grouser |

|

{mm) Track pitch (mm) |

203.2 |

|

{mm) Track width (mm) |

Optional 560 |

|

Number of track shoesieach side) |

37 |

|

Length of track on ground (mm) |

2430 |

|

Track gauge (mm) |

1880 |

HYDRAUUC SYSTEM OF WORK EQUIPMENT

|

Working pressure (Mpa) |

14 |

|

Rated flow (L/min) {2500r/min) |

280 |

|

Pump |

Gear pump |

|

Control valve |

Hand-operated, sliding type |

|

Cylinder, Bore x Rod x Stroke (mm) |

φ110x 065x1026 |

SUNDER CARRIAGE

|

Sprocket |

Segmented |

|

No. of carrier roller (each side) |

2 |

|

No. of track rollers (each side) |

6(4 Single, 2 double) |

|

Track tension |

Hydrau lie - adjusted |

Floating seals are used in all sprockets, track rollers, carrier rollers and

TRAVEL SPEED (km/h)

|

|

1st |

2nd |

3rd |

|

Forward |

3.8 |

6.6 |

10.6 |

|

Reverse |

4.9 |

8.5 |

13.6 |

WORK EQUIPMENT

|

Blade type |

Straight tilt blade |

Angle |

U dozer |

Folded blade |

|

Width x Height (mm) |

3416x1150 |

4019x1050 |

3400x1150 |

Work=4019x1050 Transportation:2995x1050 |

|

Max.lift above ground (mm) |

1090 |

1110 |

1090 |

1130 |

|

Max.drop below ground (mm) |

530 |

530 |

530 |

530 |

|

Pitch adjustment (° ) |

55 |

55 |

55 |

55 |

|

Max. Tilt (mm) |

400 |

/ |

400 |

400 |

|

Blade capacity(m3) |

4.5 |

4.5 |

5.6 |

4.5 |

|

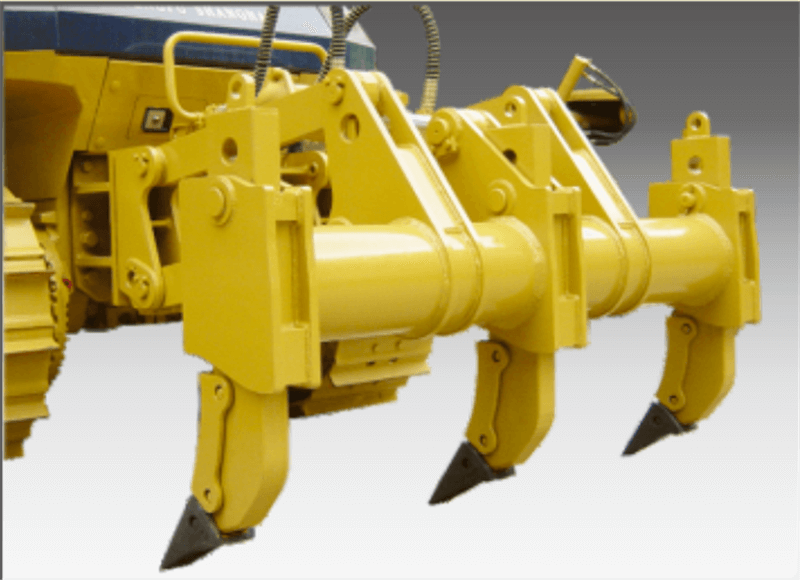

Ripper |

|

|

Type |

Three |

|

Max. dig below ground(mm) |

572 |

|

Max. lift above ground (mm) |

592 |

|

Weight (kg) |

1700 |