Main Features:

◊ Optimal design in overall appearance and structure strength.

◊ Electronic engine meeting China stage III off-road emission standard adopted for high power rise, big output torque, fuel saving and excellent reliability.

◊ Hydraulically controlled drive, automatically speed regulating and non-stop gear shifting.

◊ 3-element, single stage, single phase torque converter for higher efficiency and bigger capacity.

◊ The hexagonal cab offers excellent visibility, the powerful ventilation and unparalleled dust-free.

◊ The final drive uses triangle Spline and tip relief, crowned gear drive for enhanced balance and the stability during power transmission, and increased life.

◊ Integrated moulded plastic console with LCD panel and gauges to realize real-time monitoring efficiently and reliably.

◊ Alarming & monitoring system is efficient and reliable.

◊ Centralized pressure checking easy for malfunction diagnosis.

◊ Ergonomics design in controls to reduce operator's fatigue.

◊Use automatic dust discharge type air pre-cleaner for more adaptable in working in dust surroundings

Advantages:

◊ Compliant with China off-road emission standard stage III.

◊ Provide the high power rise, maximum output torque at low speed, and excellent adaptability.

◊ Dated double pulse injection cam and advanced CELECT fuel system combined to realize efficient fuel injection.

◊ Charge air cooling technology used in engine improves reliability, power output, fuel economy and exhaust emission.

◊ New integrated aluminum piston used to meet performance demands and emission regulations.

◊ Robust and precise balance design for crankshaft.

◊ Dated high-performance turbocharger with wastegated design.

◊ Monitoring engine in jobs all time for rapid malfunction code responding, easy for malfunction diagnosis.

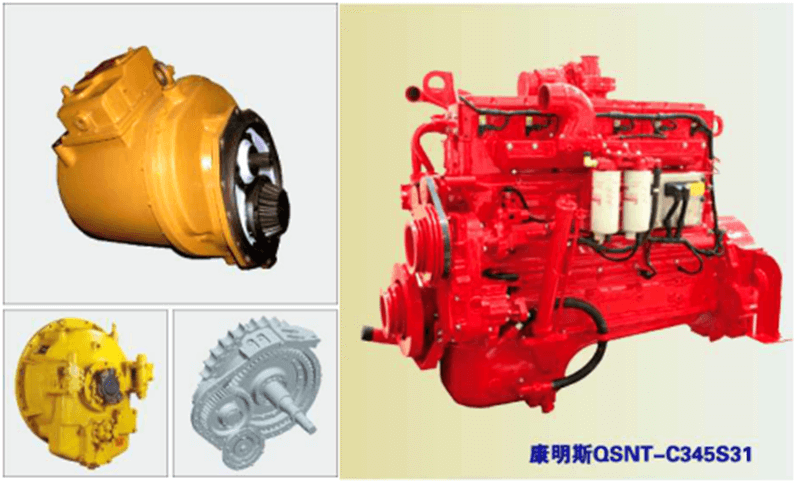

Transmission

This machine is equipped with transmission of planetary gear and rotary lockup multi-disc clutch hydraulically engaged and force lubricated. Forward 3 speeds and reverse 3 speeds can be gained by actuating hydraulic control valve.

Hydraulic Torque Converter

Hydraulic torque converter is a newly developed product with the improvement made to the material, process and layout based on introduced advanced international technology. It features simple archite cture, easy maintenance, low noise, excellent reliability.

Torque converter is of 3-element, 1-stage, 1-phase, centripetal turbine type with simple structure but good technology. It provides high power efficiency, great penetration, big capacity and less loss when the turbine

Final Drive

We, as the first domestic company, master the techn ology in the manufacturing tip relief, crowned gear which features heavy load capacity, stable drive and long life.

|

ENGINE |

Cummins QSNT-C345S31 CUMMINS |

|

RATED POWER (VSD320Y-6) |

257kW |

|

WEIGHT (VSD320Y-6) |

34400kg |

ENGINE

|

Model |

Cummins QSNT-C345S31 Cummins QSNT-C345S31 |

|

Type |

4-cycle, straight vertical, 6-cylinder, electronic injection, turbocharged, charge air cooled |

|

Rated power(kW) |

345HP (257KW) |

|

Rated speed (r/min) |

2000 |

|

Number of cylinders-bore x stroke (mm) |

6-0139.7x152.4 |

|

Starting method |

Electric starting 24V 11kW |

|

Battery |

24V{12Vx2) |

|

Air cleaner |

Dry type, horizontal, with self- dust-discharge pre-cleaner |

|

Min fuel consumption ratio(g/kwh) |

201 |

TRANSMISSION

|

Torque converter |

3-element, Single-stage, Single-phase |

|

Gearbox |

Planetary gear, multiple-disc clutch, hydraulic actuated, forced lubrication by gear pump, 3forward and 3 reverse speeds |

|

Bevel gear |

Helical bevel gear, splash lubricated |

|

Steering clutch |

Wet, Multiple-disc clutch, spring loaded, hydraulic released |

|

Steering brake |

Wet, band brake, operated with hydraulic booster |

|

Final drive |

Spur gear, double reduction, splash lubricated |

TRACK

|

Type |

Master pin type, Single grouser |

|

Track pitch (mm) |

228.6 |

|

Track width (mm) |

560 |

|

Number of track shoes each side) |

41 |

|

Length of track on ground {mm) |

3150 |

|

Track gauge (mm) |

2140 |

HYDRAUUC SYSTEM OF WORK EQUIPMENT

|

Working pressure (Mpa) |

14 |

|

Rated flow {L/min) (1795r/min) |

360 |

|

Pump |

CBW6200 gear pump |

|

Control valve |

Hand-operated plunger servo controlling |

|

Cylinder, Bore x Rod x Stroke (mm) |

O140x 075x1340 |

SUNDER CARRIAGE

|

Sprocket |

Segmented |

|

No. of carrier roller (each side) |

2 |

|

No. of track rollers (each side) |

7(2 Single, 5 double) |

|

Track tension |

Hydraulic - adjusted |

Floating seals are used in all sprockets, track rollers, carrier rollers and

TRAVEL SPEED (km/h)

|

|

1st |

2nd |

3rd |

|

Forward |

3.6 |

6.6 |

11.5 |

|

Reverse |

4.4 |

7.8 |

13.5 |

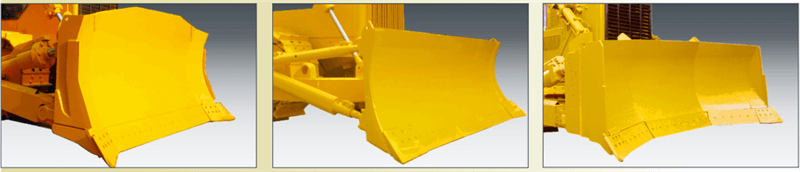

WORK EQUIPMENT

|

Blade type |

Straight tilt blade |

Angle |

U dozer |

|

Width x Height (mm) |

4130x1590 |

4850x1140 |

4225x1745 |

|

Max. lift above ground (mm) |

1560 |

1560 |

1560 |

|

Max.drop below ground (mm) |

560 |

560 |

560 |

|

Pitch adjustment (。) |

55 |

55 |

55 |

|

Max. Tilt (mm) |

1000 |

1000 |

1000 |

|

Blade capacity(m3) |

10.4 |

6.3 |

12.3 |

|

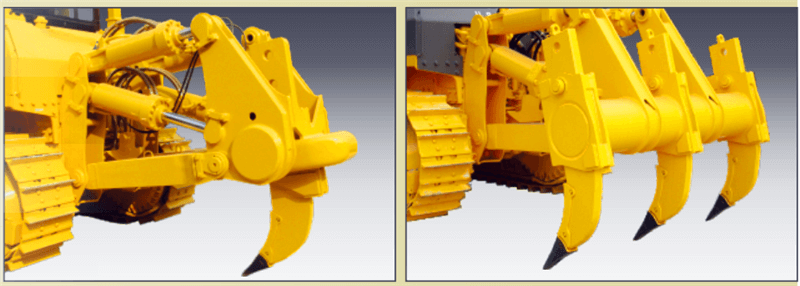

Ripper |

|

|

|

Type |

Single ripper |

Three-ripper |

|

Max. dig below ground(mm) |

1250 |

842 |

|

Max. lift above ground (mm) |

955 |

883 |

|

Weight (kg) |

3937 |

5142 |