◊ The machine features reasonable layout, excellent performance and advanced technology.

◊ Higher engine power reserves efficiency, bigger torque output, lower fuel consumption, while better reliability.

◊ Hydraulic controlled drive, automatically speed regulating and non-stop gear shifting.

◊ The final drive uses triangle Spline and tip relief, crowned gear drive to enhance the balance and the stability of the load of transmission Part.

◊ The novel hexahedral cab offers excellent visibility, the powerful ventilation and unparalleled dust-free.

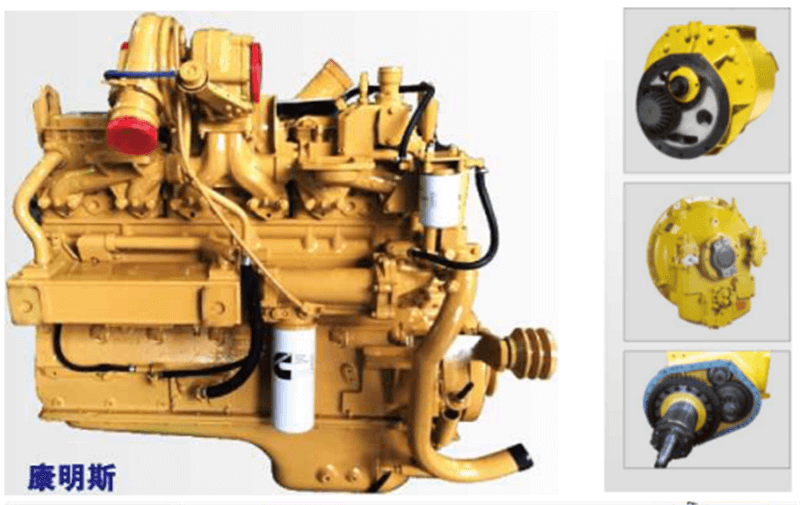

♦ Adopt Cummins CELECT electronic-control fuel system.

Cummins CM876 Core II electronic-control module adopted for Stable and precise Control.

♦ UVSDated strong—performance turbocharger with wastegated design.

♦ New aluminum integrated piston used to meet performance demands and emission regulations.

Compact configuration and connector design provides excellent power match solution.

♦ Advanced electronic Controls for precise operation.

♦ Advanced diagnosis and interface technology for good power match and engine service.

Gearbox

Hydraulic controlled gearshift is realized by operating the control valve, and without having to stop the machine, when operated with the torque converter to save operator effort.

The transmission is combined with four planets lines and a rotary lock-up clutch, multiple disc clutch, hydraulic controlled release, forced lubrication, with 3 speeds forward and 3 speeds backward.

Torque converter

The hydraulic torque converter for is a newly developed product with the improvement made to the material, process and layout based on introduced Japan KOMATSU technology. It features simple architecture, easy maintenance, low noise, excellent reliability, stepless speed regulating which ensure perfect match to the machine for an outstanding traction and a stable transmission.

Final Driving

The final drive uses triangle Spline and tip relief, crowned gear drive for enhanced balance and the stability during power transmission, lower noise, excellent reliability and added life.

|

ENGINE |

Cummins QSNT-C235 CUMMINS |

|

RATED POWER |

175kW |

|

WEIGHT (VSD220Y-6) |

23600kg |

|

WEIGHT (VSD220YS-2) |

26300kg |

ENGINE

|

Model |

Cummins QSNT-C235 |

|

Type |

Vertical, 4-cycle, water cooled, electronic injection fuel system and control system-CELECT |

|

Rated power (kW) |

175 |

|

Rated speed {r/min) |

1800 |

|

Number of c^linders-bore x stroke (mm) |

6-0139.7x152.4 |

|

Starting method |

24V 11kW 启动马达 Starting motor 24V 11kW |

|

Battery |

24V(12Vx2) |

|

Air cleaner |

Dry horizontal type with pre-cleaner |

|

Min fuel consumption ratio((g/kwh)) |

205 |

TRANSMISSION

|

Torque converter |

3-element, single-stage, single-phase |

|

Gearbox |

Planetary gear, multiple-disc clutch, hydraulic actuated, forced lubrication by gear pump, 3 forward and 3 reverse speeds |

|

Bevel gear |

Helical bevel gear. Splash lubricated |

|

Steering clutch |

Wet, muitiple-disc clutch, spring loaded, hydraulically released |

|

Steering brake |

Wet, band brake, operated with hydraulic booster and valve inner linkage |

|

Final drive |

Spur gear, double reduction, splash lubrication |

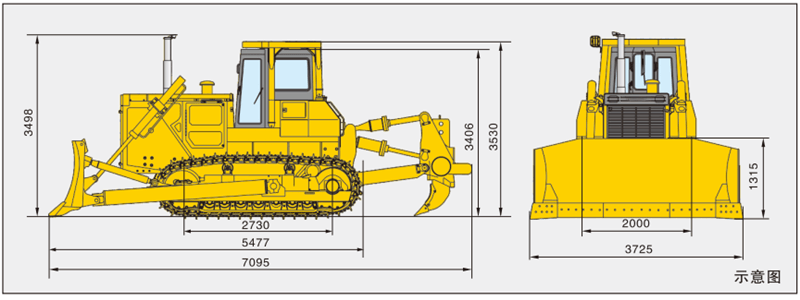

TRACK

|

Type |

Sealed single grouser |

|

Track pitch (mm) |

216 |

|

Track width (mm) |

560 |

|

Number of track shoesieach side) |

38 |

|

Length of track on ground {mm) |

2730 |

|

Track gauge (mm) |

2000 |

HYDRAUUC SYSTEM OF WORK EQUIPMENT

|

Working pressure (Mpa) |

13.7 |

|

Rated flow (L/min) {2000r/min) |

257 |

|

Pump |

CBT3160 CBT3160 gear pump |

|

Control valve |

Hand-operated plunger servo controlling |

|

Cylinder, Bore x Rod x Stroke (mm) |

CD120x (D 70x1043 |

SUNDER CARRIAGE

|

Sprocket |

Segmented |

|

No. of carrier roller (each side) |

2 |

|

No. of track rollers (each side) |

6(4 Single, 2 double) |

|

Track tension |

Hydraulic - adjusted |

Floating seals are used in all sprockets, track rollers, carrier rollers and

TRAVEL SPEED (km/h)

|

|

1st |

2nd |

3rd |

|

Forward |

3.6 |

6.5 |

11.2 |

|

Reverse |

4.3 |

7.7 |

13.2 |

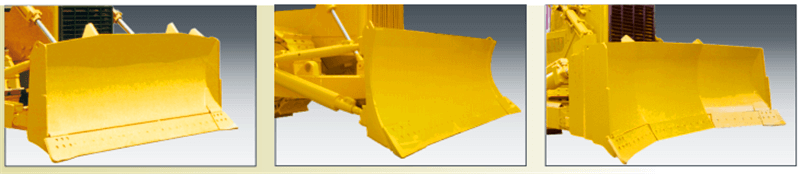

WORK EQUIPMENT

|

Blade type |

Straight tilt blade |

Angle |

U dozer |

|

Width x Height (mm) |

3725x1315 |

4365x1055 |

3684x1255 |

|

Max. lift above ground (mm) |

1210 |

1210 |

1210 |

|

Max. drop below ground (mm) |

540 |

535 |

540 |

|

Pitch adjustment (° ) |

55 |

55 |

55 |

|

Max. Tilt (mm) |

735 |

/ |

735 |

|

Blade capacity(m3) |

6.4 |

4.7 |

6.5 |

|

Ripper |

||

|

Type |

Single ripper |

Three-ripper |

|

Max. dig below ground(mm) |

666 |

666 |

|

Max. lift above ground (mm) |

598 |

555 |

|

Weight (kg) |

2572 |

2570 |